If you live in the northern half of the country like I do, the hot summer will soon change to a cool fall. The leaves begin to change and the cold months of October and November will soon bring a rush of cold-weather battery performance complaints to your counter.

Because a conventional battery retains only 40% of its electrical discharge capacity at 0F, it’s no wonder that the first cold snap brings out the worst in batteries and the best in battery sales.

But, as any experienced technician well knows, selling the battery is often the simplest part of the transaction. If, for example, the engine fails to start a few weeks after the sale, the customer immediately suspects he has a warrantable battery. Or if the customer bought a sub-standard battery at a local discount store, his vehicle might begin to develop cold-weather engine starting complaints that can be tough to diagnose in a warm shop setting. In any case, a service tech should be ready to exhibit some battery expertise when temperatures plunge.

Battery Performance

It goes without saying that the key to solving battery performance complaints is to understand how batteries work. At its most basic level, the 12-volt lead-acid battery is built with six cells, each containing an equal number of positive and negative grids or “plates.” These lead plates are suspended in a sulfuric acid electrolyte with a specific gravity of about 1.25 times the weight of pure water.

The battery’s cold cranking amps (CCA) depends very much on the number and thickness of its plates. Most automotive starter batteries are built with thinner and more numerous plates that are capable of a very high discharge rate for cranking engines.

Modern automotive starter motor batteries are rated in cranking amperes (CA) and CCA. CA is rated at 32F and is used in climates that don’t normally experience sub-freezing temperatures.

CCA is rated at 0F and is used in climates that normally experience sub-freezing temperatures. An automotive starting battery with an 800 CCA rating is designed to supply 800 amperes of current for 30 seconds without reaching its usable performance limit of 7.2 volts.

Terminal Voltage

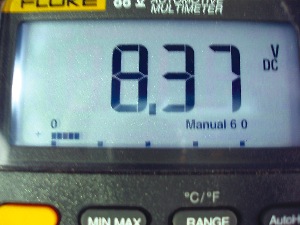

It’s imperative to remember the importance of battery terminal voltage in dealing with cold-weather battery performance complaints. When fully charged, each battery cell produces 2.1 volts. When six of these cells are connected in series to make a 12-volt battery, they produce 12.6 open-circuit volts (OCV) between the battery’s positive and negative terminals when the battery is fully charged.

OCV indicates that the battery isn’t connected to the vehicle’s electrical system. As the battery discharges, the open-circuit voltage begins to drop. At 12.4 volts, the battery is approximately 70% charged. At 12.2 volts, the battery is approximately 50% charged. At 12.06 volts, the battery is less than 25% charged.

Terminal voltage is important in modern vehicles because 10 volts must be maintained during cranking to adequately power on-board computers and modules. If the battery voltage drops below 10 volts, the adaptive memory contained in the vehicle’s Powertrain Control Module (PCM) might be erased. This can cause hard-starting or cold-engine performance problems.

Here again, a substandard battery will not produce enough CCA to maintain 10 volts in the vehicle’s electrical system while cranking a cold engine.

As the battery ages, its CCA diminishes. On a rare occasion, one positive and one negative plate might contact each other, which can cause the battery cell to discharge. If the battery cell is completely discharged, the terminal voltage can be reduced by as much as 2.1 volts. If the battery terminal voltage drops below 10 volts during cranking, the vehicle may begin to experience starting and engine performance complaints.

Modern Failure Patterns

Due to the sheer volume of on-board electronics contained in the modern vehicle platform, an entirely different type of demand is placed upon the modern 12-volt battery. Thirty years ago, a bad battery was associated with a slow-cranking, hard-to-start engine. But, thanks to quick-starting electronic fuel injection and the low current draw of a modern permanent magnet starter, a bad battery can successfully crank the engine until it completely fails.

While cranking the engine is the primary function of any storage battery, the secondary function is to keep the vehicle’s electronic modules powered up after the vehicle is parked. In many cases, some electronic systems require at least two and perhaps eight hours to completely “time out” or shut off the half-dozen or so electronic control modules contained in the modern vehicle.

The small amount of current required to keep vehicle electronics powered up is called parasitic draw. In most cases, parasitic draw generally shouldn’t exceed 50 milliamperes (mA) two hours after vehicle shut-down. At 50 mA, a battery rated at 60 amp-hours will last about six weeks. If the vehicle is driven on short trips, the parasitic draw time will exceed the charging time on the battery and the battery will eventually go dead.

In some cases, a module can “wake up” in the middle of the night and turn on the interior lights or activate some other electrical function that can run the battery down. Because these failures are usually intermittent, they can be very difficult to solve.

Other causes of battery failure include battery plate sulfation caused by the vehicle not being driven and low charging rates caused by a faulty alternator, alternator drive belt, or voltage regulator. Because modern vehicles use the engine’s PCM to regulate alternator voltage output, most charging system failures are caused by the alternator developing a bad diode or by a sticking or worn carbon brush.

Electrical Literacy

At this point, let’s review the three measures of electrical flow, which are volts, amps and ohms. Using the “garden hose” analogy, voltage is equivalent to the water pressure in the hose. Amperage would be equivalent to the volume of water flowing through the hose. The resistance measured in ohms would be equivalent to the water nozzle fastened to the end of the hose.

When the nozzle is closed and no water is flowing through the hose, we have what is called open-circuit voltage or OCV. As the nozzle is opened, the water flow (current) increases and the water pressure (voltage) decreases. If we remove the nozzle entirely, water pressure drops to zero and the hose is flowing at full volume. This would be equivalent to a dead short in the electrical system that causes the wiring to burn and the battery to explode.

Battery Safety Basics

Because handling and testing is part of selling batteries, it’s important to follow all posted safety rules. In summary, it’s important to use safety goggles, rubber aprons and rubber gloves to protect eyes, clothing and hands from acid burns caused by the sulfuric acid contained in battery electrolyte. Always remember that, if electrolyte is splashed into your eyes, immediately flush your eyes with tap water and seek medical attention.

Because battery charging produces explosive hydrogen gas, any battery service room should be well-ventilated. Before connecting a battery charger, identify the correct polarity of the battery terminals. Attach the battery charger’s red cable to the battery positive and the black to the battery negative terminals. After recharging, turn the battery charger off and remove the negative cable first to prevent an electrical spark.

Battery Charging Rates

Recharging batteries for testing is also part of cold-weather battery sales. Absorbed glass mat (AGM) batteries require a charging rate of 10 amperes or less to prevent damaging the gelled electrolyte. For conventional batteries, a 10-amp charging rate on conventional batteries is also preferred. In an emergency, a faster charging rate of about 20-30 amperes can be used to recharge a battery in about two hours.

Higher charging rates on automotive batteries tend to boil the electrolyte. If the battery case appears wet after charging, the case is coated with electrolyte and should be cleaned with a commercial acid neutralizer or a baking soda/water solution and flushed with fresh water.