Service Tips and Guidelines

• Rotors should wear evenly. The plates of the rotor should wear at the same rate. If one plate is thinner, it will affect the thermal and structural properties of the rotor.

• Always replace calipers in pairs. Failing to do so can result in a braking imbalance or pull.

• If the pads and rotor have been worn past recommend levels, inspect the caliper’s piston boot and the piston. Once the piston has been out so far, it may not retract properly.

• Corrosion on the outside of a caliper can extend inwards to the bore of the guide pins and squeeze the bushings. Replacement of the caliper is recommended.

• Brake wear should be the same on both sides of the axle.

• The piston seal loses its flexibility as it ages. This will not allow the piston to return to its rest position. This can cause the brakes to drag and increase pad wear.

• Follow the recommended OE procedure to adjust the parking brake. Not doing so may result in overheated brake pads.

• Once a brake pad has been heat tortured, it is done.

• All calipers should be inspected for wear and damage to the piston boots and seals. Piston boots can be punctured by road debris or improper installation. A puncture will allow moisture and other corrosive material into the piston seal area causing damage to the seal.

• Tapered pad wear is normal for some vehicles, especially for small rear floating caliper designs used on rear brakes. Check for a wear specification in the service information.

• Some electronic brake distribution may have faster than normal rear brake pad wear rates. This is normal in some cases. The reason for this wear is because the rear brakes are used to control nose dive. If the wear is greater than expected, check for TSBs. Often, the OEM will issue new software for the hydraulic control module that solves the problem.

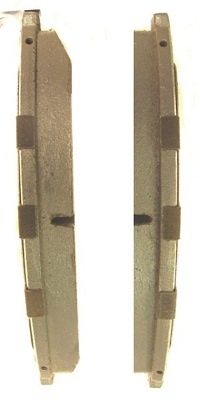

Even Wear

Pads have equal amounts for friction material, within 2-3 mm, on both pads.

Cause: Brake caliper and connected hydraulics are operating properly.

Solution:

• Replace the brake pads.

• Replace hardware including abutment and anti-rattle clips.

• Service caliper guide pins and slides.

Outer Pad Wear

The outboard brake pad shows increased wear when compared to the inboard pad.

Causes:

• Outer pad is continuing to ride on the rotor after the caliper releases.

• Caliper guide pins and bushings seized.

• Pads seized in slides.

Solution:

• Replace the pads.

• Service caliper guide pins and bushings. Replace if necessary.

• Service caliper slides and lubricate.

• Inspect the caliper for damage to the guide pin holes. Replace if damaged or corroded.

Inner Pad Wear

The inboard pad shows increased wear when compared to the outboard pad.

Causes:

• Worn caliper piston seal not allowing the piston to return to the rest position.

• Caliper guide pins and bushings seized.

• Pads seized in slides.

• Piston has damage or corrosion.

• Problem with the master cylinder.

Solution:

• Replace the pads.

• Inspect the hydraulic brake system and check for residual brake pressure.

• Service caliper guide pins and

bushings. Replace if necessary.

• Service caliper slides and lubricate.

• Inspect the caliper for damage to the guide pin holes and piston boot. Replace if damaged or corroded.

Tapered Pad Wear

Friction material is worn in a wedge pattern. This can happen horizontally or vertically.

Causes:

• Errors during the installation of the pads.

• Worn caliper guide pin bushings.

• One guide pin or slide seized.

Solution:

• Replace the brake pads.

• Service caliper guide pins and bushings. Replace if necessary.

• Service caliper slides and lubricate.

• Inspect the caliper for damage to the guide pin holes. Replace if damaged or corroded.

Cracking, Glazing or Lifted Edges on the Pads

The friction material on the pads is damaged physically and shows signs of thermal distress.

Causes:

• Driver overused the brakes.

• Improper bedding/break-in procedure when the pads were installed.

• Defective brake pads.

• Hydraulic system problems preventing the release of pressure.

• Caliper not about to release due to seized components.

• Parking brake not retracting fully.

Solution:

• Replace the brake pads. Re-evaluate pad selection.

• Perform recommended break-in procedure.

• Inspect the caliper for damage to the guide pin boots and piston boot. Replace if any signs of heat damage are present.

• Service caliper guide pins and bushings.

• Service caliper slides and lubricate.

• Inspect the caliper for damage to the guide pin holes. Replace if damaged or corroded.

• Adjust the parking brake.

Overlapping Friction Material

The top edge of the pad overlaps the top of the rotor.

Causes:

• The wrong rotor or pad on the vehicle.

• Worn guide pins, caliper bracket or caliper.

Solution:

• Replace the pads.

• Check rotor diameter with OE specifications.