We all like to think tires are one of the most technologically advanced parts on a vehicle. Unfortunately, many of our end-user customers don’t see it that way. To the vast majority of the tire-buying public, tires are round and black, and that’s about it.

To put it simply, we need to be better educated so we can educate them.

So, we are going to focus on the many elements of tire technology and drill down to the basics. In this two-part Tire Review exclusive series, we are going to talk about the information on the sidewall, tire pressure and load, UTQG, DOT, vehicle load carrying capacity, tire rotation, the effect of time and temperature on tire pressure and much more. You may know some of this, but it’s always good to brush up and/or learn something new. The idea here is the more you know about the inner workings and technology of tires, the better you’ll be able to sell them. Let’s start with some basics.

Tire Sidewall

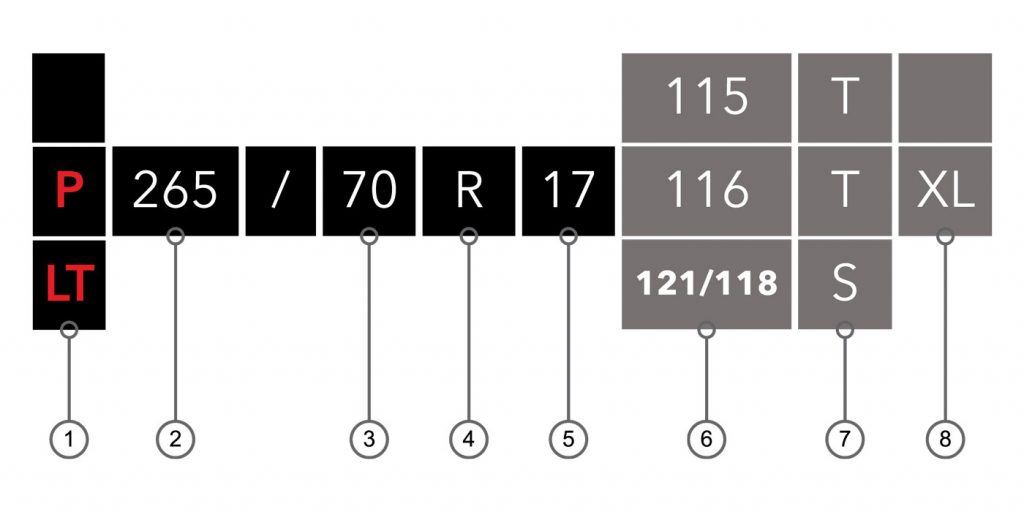

The information molded on the tire sidewall helps us better understand the tire’s intended purpose as well as dimensions, load capacity, high temperature/high-speed durability, year and week of production and more. Better understanding this information will help us explain to customers how they can choose the right set when it’s time to replace their tires. Picture 1 shows a typical tire sidewall and the information on it.

Service Type or Size Designation

Some tire size designations start with a letter(s) that identifies the type of vehicle and/or type of service for which they were designed. Passenger tires that are designed based on the Tire and Rim Association’s (TRA) standards start with the letter “P” and are known as P-metric size tires. Passenger tires designed based on the European Tyre and Rim Technical Organization’s (ETRTO) standard start without any letters and are known as hard-metric or Euro-metric sizes. Euro-metric sizes are dimensionally equivalent to P-metric sizes but typically differ subtly in load carrying capabilities.

Light truck tires designed based on TRA standards often start with “LT” and are designed for vehicles capable of carrying heavy cargo or towing large trailers, such as pickup trucks. In older size conventions, the LT designation may be at the end of the tire size, which designates flotation light-truck sizes. A Euro-metric size designed for carrying cargo and/or towing often ends with the letter “C” which signifies the tire is a “commercial” tread intended for vans or delivery trucks. A tire size that begins with a letter “T” signifies the tire is a temporary spare or mini-spare.

One of the most often asked questions is, “what are the differences between P-metric, Euro-metric and LT-metric tires, and which one should we recommend to customers?” There is also a debate as to whether you can substitute one type of tire with another.

When it comes to replacing tires for a passenger car, SUV or pickup trucks, the most important consideration is to maintain sufficient load carrying capacity. Same size LT-metric tires, in comparison to the same size P-metric or Euro-metric, may have similar dimensions, but they usually have a higher load capacity, and as a result, operate at higher inflation pressures. LT-metric tires are designed to carry a higher load, and therefore, have very different construction and contour. So, replacing LT-metric tires with a P-metric or Euro-metric, and vice versa, is never recommended.

TRA and ETRTO sizing are very similar. The two standards use different calculations to determine a tire’s maximum load carrying capacity. Oftentimes, Euro-metric tires have a higher load carrying capacity than same size P-metric tires. There are several tire companies that allow replacing P-metric tires with Euro-metric tires when the maximum load carrying capacity is equal or higher. But they caution replacing Euro-metric to P-metric same size tires and require checking the maximum load carrying capacity of both before the tire change is recommended. The majority of tire companies develop P-metric and Euro-metric tires the same way; however, it’s always wise to stay with the same tire designation that came OE on the vehicle when possible.

To illustrate this topic, let’s take a P215/60R16 and 215/60R16 tire. They are both popular sizes and fit on several sedans in the market. They both have similar dimensions, but the P215/60R16 has a load index of 94 with maximum load carrying capacity of 1,477 pounds at 35 psi, while the 215/60R16 has a load index of 95 for a maximum of 1,521 pounds at 36 psi. While changing a P-Metric tire with a Euro-Metric provides sufficient load capacity, swapping Euro-metric to P-metric should be checked with tire manufacturers.

Finally, don’t mix P-metric and Euro-metric tires on a car since it could compromise ride, handling, braking and cornering performance.

Tire Dimensions

The three-digit numeric code (No. 2 on Picture 1) on the sidewall identifies the tire’s section width in millimeters, which is 265mm in this example. The actual tire may not match perfectly to this, but it is close. The two-digit number following the section width (No. 3 on Picture 1) identifies the tire’s aspect ratio, identified as a percentage of the section height divided by the section width. In Picture 1, the aspect ratio of the tire is 70%, so the section height of tire will be 185.5mm. The higher the aspect ratio, the taller the tire sidewall is (same width tire).

The letter “R” following the tire aspect ratio identifies the tire’s construction as a radial tire. Rarely will you see a tire with the designation of “D,” which identifies that the tire has a bias ply construction meaning the body plies crisscross on a diagonal. The last two digits on tire size (No. 5 on Picture 1) refer to the rim diameter of a tire. The two digits identify the size of the wheel that the tire is intended to fit.

Service Descriptions

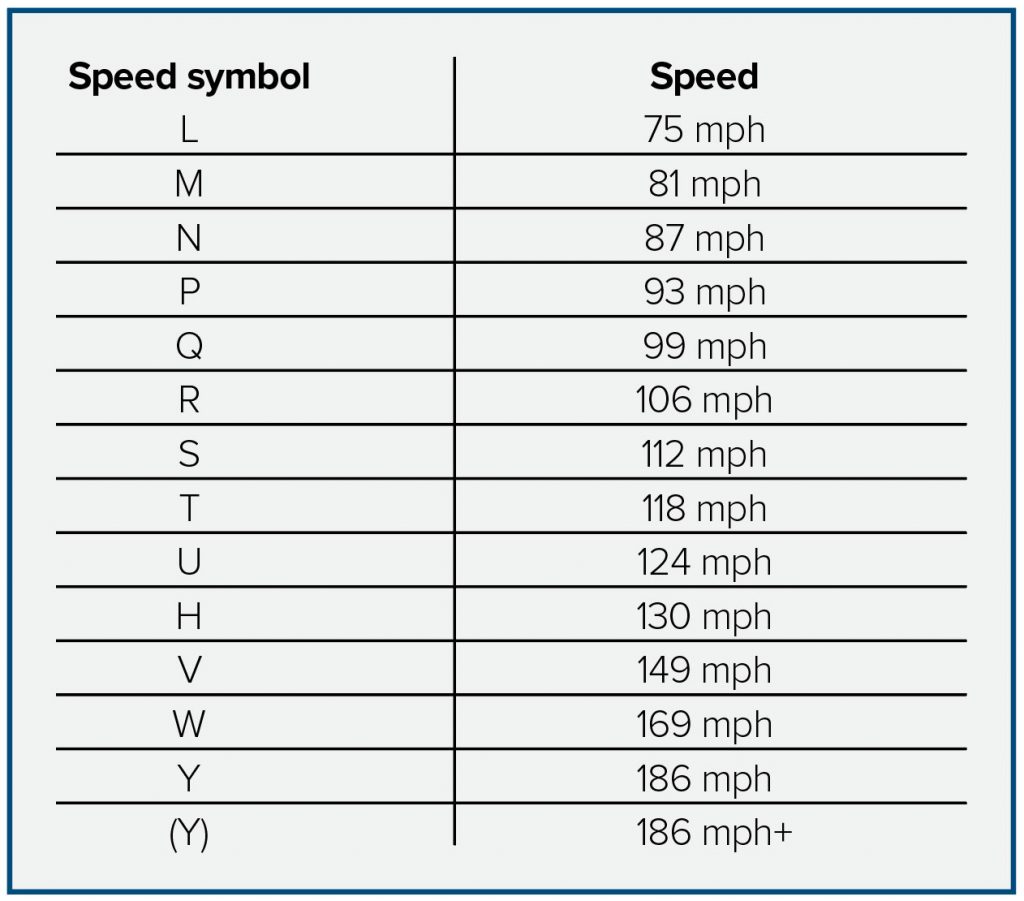

The two- or three-digits after the rim diameter (No. 6 on Picture 1), along with the letter next to it (No. 7 on Picture 1) are known as service descriptions. Service descriptions show the maximum loading capacity of a tire along with the maximum speed and condition that the tire can be run.

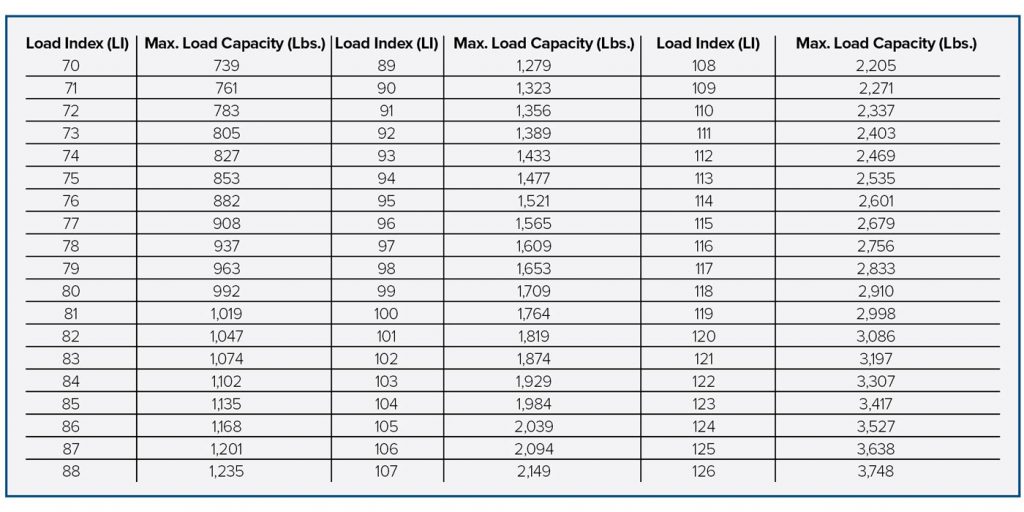

Table 1 shows the typical passenger tire load index along with the maximum loading capacity. The maximum loading capacity at maximum pressure is also available on the tire sidewall. In Picture 1, a load index of 116 on a P265/70R17 will be a maximum of 2,756 pounds of load per tire. In addition, passenger tires are also identified as light load (LL), standard load (SL) or extra load (XL) on the sidewall. This is the same in both P-metric and Euro-metric sizes, however, the inflation pressure at maximum load slightly varies between the two.

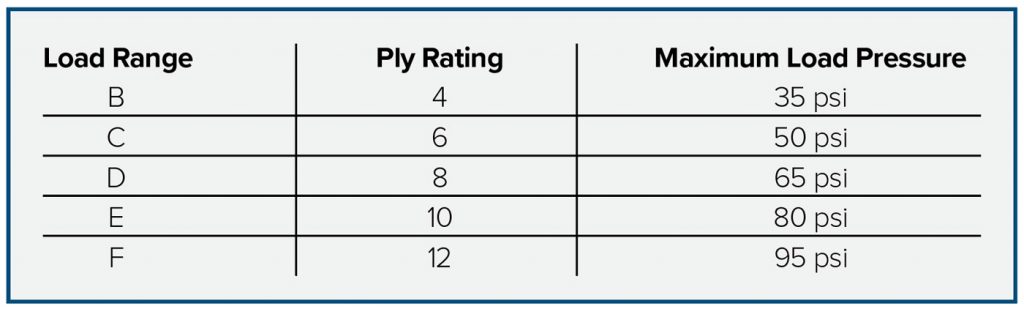

Light-truck tires are identified by load range, which varies from load range B to load range F. The majority of tires in the market are load range C, D and E. Table 2 shows the load index in the tire. Each load index in light truck sizes are also identified by two numbers (No. 6 on Picture 1). The first number is the maximum load in single wheel (2 tires on rear). The second number is the maximum load in dual-vehicle applications (4 tires on rear). In Picture 1, 121/118 represents the maximum load of 3,197 pounds in single and 2,910 pounds on a dual application.

Table 3 illustrates the speed capability of tires. Speed ratings were established to match the speed capability of tires with the top speed of the vehicles to which they are applied. Speed rating does not suggest the speed of the vehicle and only shows the tire’s maximum capability. A tire’s maximum load (Table 2) is the most weight the tire is designed to carry. Since a tire’s load carrying capacity is related to the tire’s size and how much inflation pressure is actually used, maximum loads are rated with the tire inflated to an industry-assigned inflation pressure.

Inflation Pressure

The main job of a tire is carrying a vehicle load, but that won’t happen if the tire is not inflated. OEMs assign a tire size with a specific pressure when they release a vehicle in order to carry the load of the vehicle, its passengers and provide the best balance of handling, traction, fuel efficiency and durability. The inflation pressure that can run the vehicle is almost always different than what’s on the sidewall, which indicates the maximum pressure and corresponding load for the tire. That’s often not the pressure at which the vehicle operates. The pressure which a vehicle needs to run on can be found in the placard in the driver’s door panel. In case of a tire size change, the proper inflation pressure will be recommended to maintain the same amount of load.

Higher inflation pressure provides higher load capacity, and that’s why light load passenger tires have maximum load pressure of 35/36 psi, while extra load passenger tires have a maximum load pressure of 41/42 psi.

Inflation pressure also has a direct effect on fuel efficiency, traction and wear. As inflation pressure reduces, fuel efficiency of the tire will be reduced. Lower inflation pressure can also produce more friction on the shoulder area and cause early shoulder wear. At the same time, higher inflation pressure can cause more friction on the center area and result in early center wear.

Tire pressure does not stay constant during vehicle operation, and that’s why it’s recommended to be checked regularly. According to a study conducted by the National Highway Traffic Safety Administration, 27% of passenger cars have at least one tire that’s underinflated by 8 psi or more. Higher temperatures increase the tire pressure, and that’s why the tire pressure should always be measured cold. For every 10-degree drop of temperature, tires roughly lose 1 psi.

Also, tire pressure will reduce over time. Tires can lose one psi per month under normal conditions, so it’s always recommended to check the pressure regularly.

In part 2 of this series, we’ll further discuss tire basics, including DOT information, UTQG warning and much more.

Check out the rest of the January digital edition of Tire Review here.