9 Rules of Bearing Replacement

Rule 1: Realize the amount of load that bearings withstand. On a typical passenger vehicle weighing around 3,400 pounds, each pair of front-wheel bearings, as well as the rear-wheel or axle bearings, support around 850 pounds depending on the weight distribution and driveline configuration. If it’s a 6,000 pound SUV, each bearing might carry about 1,500 pounds.

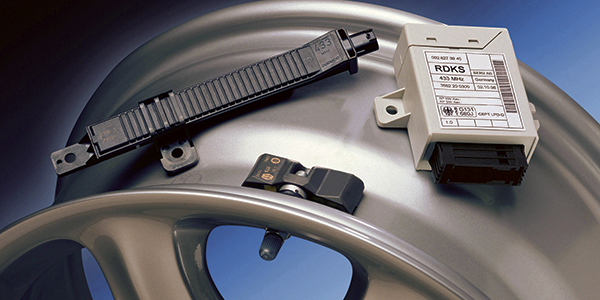

Investing In TPMS Tools

Most vehicles require some type of “stationary” relearn procedure to reset the system. This requires some type of TPMS tool to activate each of the tire pressure sensors in a specified sequence so the TPMS control module can relearn their new locations. On some GM applications, a J-41760 magnetic tool is required to “wake up” the sensors.

Spotting Bent Suspension Components

Normal driving usually won’t knock the wheels out of alignment or damage the suspension. However, normal driving also involves encounters with the unexpected, which often include potholes, curbs, railroad crossings (which are famous for being rough), parking lot speed bumps and other things that jar and stress the suspension.

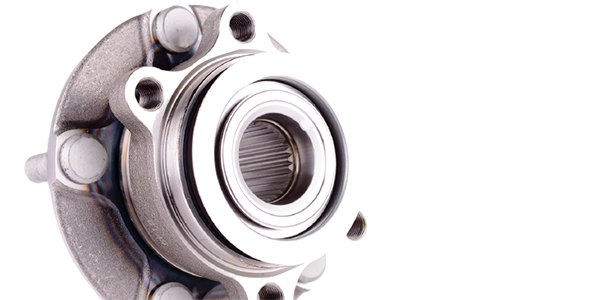

Just One Hit: Wheel Hub Replacement

When a driver hits a pothole or curb hard enough, extreme forces are put onto the balls or rollers and races of the bearing. This can result in the formation of a very small mark on the surfaces.

Brake Hose Inspection Tips to Spot the Problem Before It’s Too Late

There is no recommended replacement interval for brake hoses. That’s because brake hose conditions will differ depending on the vehicle, driver, and environment. Inspection is the only way to spot a problem before a brake failure.

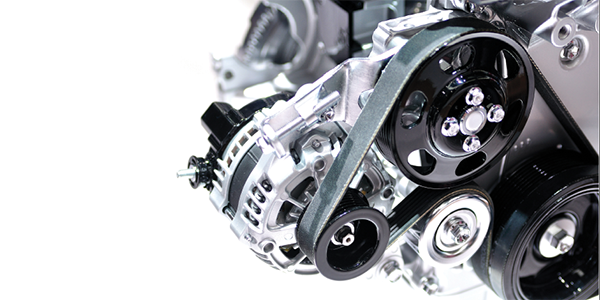

Belt Inspection Checklist

You might have only one chance to sell a customer a new serpentine belt. With belts lasting roughly 90,000 miles, proper inspection at the time of failure is critical not only for selling the belt, but also for ensuring add-on sales and better customer satisfaction.

These are the steps you should be performing on every car or truck that enters your shop.

Struts: The ‘Loaded’ Question

What can you do in 17 minutes? You could make money on those 17 minutes of billed labor installing traditional struts – or you can give up those 17 minutes to sell a more profitable part that has the potential to lower the chances of a comeback and give the customer more value.

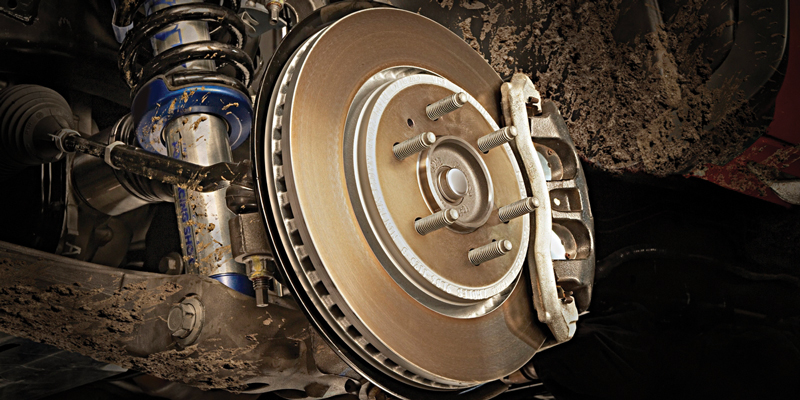

Fixing Pulsation and Judder Issues

When a customer pulls in with a complaint about brake pulsation or judder, throwing parts at a repair will not solve the problem.

TPMS and Custom Wheels

A nice set of wheels can rejuvenate the look of a vehicle. Increasing the diameter of the wheel, tire width and load ratings can boost the potential of a car or truck. But, what about the tire pressure monitoring system (TPMS) sensors?

Loaded Calipers

Caliper replacement is often the best course of action to ensure that a braking system will perform at an optimal level in terms of safety, performance and maximizing brake pad life.

Understanding Sway Bar Technology

Sway, stabilizer or anti-roll bars never get the credit they deserve. If sway bars were never invented, the ride and handling of vehicles would be a lot harsher than it is today. These bars act as a third spring, controlling rolls and stiffness of a vehicle. A sway bar has no effect if both sides

Why Oil Filters Matter to Extended Oil Change Intervals

With oil life indicators pushing the average oil change past the 6,000-mile mark, it is not just the quality of the oil that’s improved, it is the quality of the filter, as well.