Everybody wants safe brakes, right? You want the assurance that any brake linings you install on a customer’s vehicle will provide adequate braking and meet all applicable safety standards. But guess what? There are no federal safety standards for aftermarket brake linings.

Everybody wants safe brakes, right? You want the assurance that any brake linings you install on a customer’s vehicle will provide adequate braking and meet all applicable safety standards. But guess what? There are no federal safety standards for aftermarket brake linings.

Federal Motor Vehicle Safety Standards (FMVSS) 105, 126 and 135, which are issued by the National Highway Traffic & Safety Administration/Department of Transportation (NHTSA/DOT), technically apply to new vehicles only. They do not apply to aftermarket replacement brake linings. So, aftermarket brake linings are unregulated and do not have to meet the same FMVSS standards as OEM brake linings.

The FMVSS standards are designed to assure new vehicles are capable of stopping within a certain distance deemed necessary for safe driving. FMVSS 135 and 126 are the current standards that apply to new cars and the majority of the vehicles on the road.

Compared to the earlier FMVSS 105 standard, FMVSS 135 requires roughly a 25% reduction in pedal effort for the same stopping distance.

FMVSS 135 says all vehicles under 10,000 lbs. gross vehicle weight (GVW), except motorcycles, must be capable of stopping within a distance of no more than 230 feet (70 meters) from 62 mph (100 km/h) with cold brakes (under 212° F or 100° C) and with no more pedal effort than 368 ft. lbs. (500 N).

The FMVSS 135 standard also specifies a required stopping distance for vehicles should the power brakes fail (no power assist), or if one of the two hydraulic circuits fails. Under these conditions, the maximum stopping distance from 62 mph (100 km/h) is not to exceed 551 feet (168 meters) with a maximum pedal effort of no more than 368 ft. lbs. (500 N). FMVSS 135 also has a stopping requirement in the event of an anti-lock brake system (ABS) failure. The rules require the stopping distance not to exceed 279 feet (85 meters) with a maximum pedal effort of no more than 368 ft. lbs. (500 N).

There is also a hot performance stopping requirement for fade resistance. With the brakes hot, the maximum stopping distance for the second of two back-to-back panic stops is not to exceed 292 ft. (89 meters) with the same pedal effort as before (368 ft. lbs., or 500 N).

The parking brakes are also covered by FMVSS 135. The rules specify conditions under which the parking brake must be able to hold the vehicle on both an uphill and downhill incline.

FMVSS 126

Since September 1, 2012, every car manufactured or imported in the U.S. must have Electronic Stability Control (ESC) to comply with FMVSS 126. It was estimated that FMVSS 126 saves between 1,536 and 2,211 lives a year by preventing rollovers. FMVSS 126 was under construction since 2004, and is probably one of the best standards in the book because NHTSA consulted not only OEMs, but the aftermarket.

FMVSS 126 was so well researched that in 2008, they also projected vehicle costs would be no more than $380 for anti-lock brakes and an additional $111 for electronic stability control at the OE level.

The test for FMVSS 126 is “technology-neutral” and basically involves placing a robotic system in the vehicle that performs a series of maneuvers that can make a vehicle unstable. Sensors then measure how well the ESC system corrected the condition. It does not test individual components, but the vehicle as a whole.

FMVSS 126 requires vehicles modified by the aftermarket to still meet the performance requirements of the regulation. In a nu tshell, if a product affects vehicle acceleration, deceleration or handling, it needs to be tested. Even aftermarket products for appearance (lowered suspension, low-profile tires, etc.) or convenience (roof racks, etc.) may need to be evaluated for their compatibility with a vehicle’s active safety systems. This is a new twist to FMVSS standards that typically targeted new vehicles and not the aftermarket. The new regulation also specifies that these systems can’t be disabled by shops. Only the owner of the vehicle can do that.

tshell, if a product affects vehicle acceleration, deceleration or handling, it needs to be tested. Even aftermarket products for appearance (lowered suspension, low-profile tires, etc.) or convenience (roof racks, etc.) may need to be evaluated for their compatibility with a vehicle’s active safety systems. This is a new twist to FMVSS standards that typically targeted new vehicles and not the aftermarket. The new regulation also specifies that these systems can’t be disabled by shops. Only the owner of the vehicle can do that.

What does this mean for regular replacement parts and brake pad manufacturers? It means more testing and expense if the new standard is taken to its full extent. After all, brake pads and rotors are at the heart of any ESC system. But, friction material suppliers have been jointly developing test standards and procedures along with SAE for friction materials that could make testing less expensive and more consistent. Also, thanks to the efforts of SEMA, the aftermarket was granted a one-year exemption while the rule makers figure things out.

The Brake Police

With zero regulations, aftermarket brake suppliers have to police themselves and each other to assure their products are safe. No brake supplier in their right mind would sell brake linings they know are not capable of providing adequate stopping power under normal driving conditions. Even so, what is adequate is subject to interpretation, and some suppliers take a more liberal view of the bottom line requirements than others.

If you want to maintain like-new brake performance, you should be installing application-engineered or premium brake linings that have been tested and certified to meet standards similar to FMVSS 105, 135 and maybe 126.

In the Shop

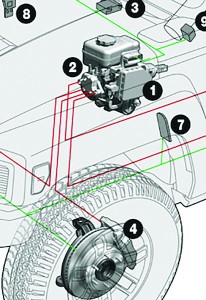

You need to pay close attention to the brake work you are doing and the kind of replacement linings and other parts you are installing on your customers’ vehicles. The hydraulic brakes and friction linings on today’s vehicles are closely integrated with the anti-lock brake, traction control and/or stability control systems on the vehicle. Consequently, any change that significantly alters the hot and cold friction characteristics of the linings has the potential of upsetting not only braking performance, but also the operation of the ABS, traction control and stability control systems.

Given the fact that aftermarket brake linings are essentially unregulated, how can you be sure the linings you are installing on your customers’ vehicles meet these criteria? The best advice here is to buy name-brand products from suppliers who stand behind their products.

For the most part, the quality and performance of most aftermarket brake linings is not in question. Laboratory tests have confirmed what the linings are designed to do, and virtually any name-brand brake lining that meets these criteria will provide safe braking and deliver performance that is similar to, or even better than, the OEM brakes on your customers’ vehicles. But there are some concerns with no-name suppliers selling products that are of questionable quality.

Some say the only way to guarantee that aftermarket brake linings meet the same safety requirements as new vehicles is to have FMVSS 105 and 135 apply to the aftermarket, too. The brake manufacturers do not want to see that happen because it would require a lot of expensive vehicle testing. Imagine the cost of having to test brake linings for every year, make and model of vehicle in an entire product line, and how that cost would have to be passed along the distribution chain to you and your customers. It could increase the cost of brake linings significantly.

Fortunately, no federal regulations are in the works for aftermarket brake linings; so, the brake manufacturers will continue to regulate themselves and each other to make sure their products are safe and deliver like-new or better-than-new performance. The bottom line, after all, is to have a happy brake customer.

Federal Investigator

Trying to see a brake system through the eyes of the OEM engineer can make you a better technician. Just like any technician, the OEM engineer has to work under certain constraints to achieve a goal that is laid out in quantifiable performance objectives, like meeting FMVSS and internal standards. Understanding how they go about this can help to make you a better technician.