Today’s tires have so much information imprinted on their sidewalls (and labels) that reading all of it is like sitting down with a book. Part of the verbiage is the Uniform Tire Quality Grade (UTQG) ratings for treadwear, traction and temperature. But what exactly do those numbers and letters mean, where do they come from, and are they actually useful in this day and age?

The U.S. Department of Transportation, through NHTSA, established the UTQG structure some 45 years ago in an effort to help the consumer better compare and purchase tires based on relative capabilities. Most passenger tires sold in the U.S. are required to undergo UTQG testing and have UTQG ratings assigned to them. LT-metric tires, winter tires, temporary spares, trailer tires, tires less than 12 inches in wheel diameter and a few other types of tires are exempt.

The DOT does not conduct the tests. Each tire manufacturer performs its own tests, or hires an independent testing company to do the tests, in accordance with procedures prescribed by the government. The tire manufacturer then assigns the UTQG ratings based on those test results. NHTSA has the right to inspect the tiremaker’s data and can fine a manufacturer if it finds inconsistencies. But, there are no routine audits; most of the problems NHTSA discovers are apparently the result of insiders providing information to regulators.

Most new tire lines have their UTQG ratings established as part of the tire development process, but manufacturers have a six-month grace period to follow up with actual production tires. Once the ratings are determined, they must be branded on the tire’s upper sidewall and printed on its paper label.

Treadwear

UTQG treadwear ratings are derived from a road test in which the test tires are run in a vehicle convoy along with standardized control tires. Test vehicles repeatedly run a government-prescribed, 400-mile test loop near San Angelo, Texas, for a total of 7,200 miles. The vehicle can have its alignment set, air pressure checked and tires rotated every 800 miles.

Both test and control tire wear is measured during and at the conclusion of the test. The tire manufacturers then assign a treadwear rating based on the observed wear rates of the test tires compared to the control tires. A tire with a 200 rating should be good for twice as many miles as the control tire. A tire with a 50 rating should wear half as long, while a tire with a 300 rating indicates it should last three times as long, etc.

There are some problems with UTQG treadwear ratings, a few that are technical in nature. The control tire is an old technology design and new batches of control tires are built every year. The new tires are rated versus the previous batch and the results are adjusted, but over the years, there has been some inflation of the test results. The test also tends to over rate tires with aspect ratios of 50 and lower.

Another problem is that the results are subject to some interpretation by tiremakers. Manufacturers are not required (nor would it be practical) to test the entire range of sizes of a particular tire, so they test a representative size or two and apply the results across the board. In practice, smaller sizes are more of a challenge because of their higher rpm rates. In addition, since treadwear ratings are assigned after a tire has only run 7,200 miles, the tire manufacturers need to extrapolate the wear data from a relatively low amount of actual treadwear.

Manufacturers are generally very cautious about rating a tire too high and running into problems with NHTSA, so the ratings often reflect, to some extent, the needs of their marketing departments. Marketers typically want to have a range of treadwear ratings that line up with how tires are positioned in the manufacturer’s product offerings. So it is common to rate a tire lower than it could be to make it properly fit within a product line.

Under-rating a tire’s treadwear is common with ultra-high performance and R-compound tires. The manufacturers often aren’t concerned with how these tires wear in actual street use and many consumers (incorrectly) equate low treadwear ratings with high levels of traction. The result is tires with ratings of 40 or 50 that could legitimately be rated much higher.

Treadwear ratings are no guarantee of actual tire mileage. They were never intended to project the exact mileage a particular tire might deliver. At best, comparing the treadwear ratings of tire lines within a single brand is somewhat helpful, but attempting to compare the grades between different brands is questionable.

A general rule of thumb sometimes used is that an average driver with an average vehicle can typically estimate the tread life of a tire by multiplying the UTQG treadwear rating by 100. For example, a tire with a treadwear rating of 700 may last approximately 70,000 miles. There is no real science supporting this “rule.”

Unfortunately, the rating that is of the most interest to consumers is the one that is the least consistent. Originally intended to be assigned in a purely scientific manner, the UTQG treadwear rating has become little more than a marketing tool used by manufacturers to help position and promote their tires.

Traction Grades

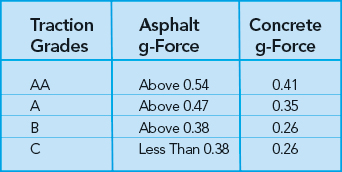

The UTQG traction grades are calculated by installing test tires on the instrumented axle of a skid trailer. A truck pulls the skid trailer at a constant 40 mph over wet asphalt and concrete test surfaces. The tow truck is equipped with an on-board water supply system that sprays water in front of the test tire. The trailer’s brakes are momentarily locked and the sensors on the axle measure the tire’s braking g forces as it slides. Because the test is based solely on a tire’s straight-line wet coefficient of friction as it skids across the test surface, it places more emphasis on the tire’s tread compound than its tread design.

The UTQG traction grades are calculated by installing test tires on the instrumented axle of a skid trailer. A truck pulls the skid trailer at a constant 40 mph over wet asphalt and concrete test surfaces. The tow truck is equipped with an on-board water supply system that sprays water in front of the test tire. The trailer’s brakes are momentarily locked and the sensors on the axle measure the tire’s braking g forces as it slides. Because the test is based solely on a tire’s straight-line wet coefficient of friction as it skids across the test surface, it places more emphasis on the tire’s tread compound than its tread design.

Put simply, it grades the tire’s ability to stop a car in a straight line on a wet test surface. The UTQG traction test does not evaluate dry braking, dry cornering, wet cornering, or high-speed hydroplaning resistance. Nor does it correlate to cold weather traction. The test is done in warm weather conditions and a tire needs high levels of styrene in its tread compound to get a high rating. The high styrene levels result in poor cold weather results.

Traction grades, from highest to lowest, are AA, A, B and C. The AA rating was added in 1997. Only about 15% of tires earn AA ratings and they tend to be performance tires. Most tires have an A rating … perfectly satisfactory for most vehicles. B and C ratings tend to be found mostly on tires designed for off pavement use.

Temperature (Resistance) Grades

The UTQG temperature rating indicates the extent to which heat is generated and dissipated by a tire. If the tire is unable to dissipate heat effectively, or if the tire is unable to resist the destructive effects of heat buildup, its ability to run at high speeds is reduced.

The UTQG temperature rating indicates the extent to which heat is generated and dissipated by a tire. If the tire is unable to dissipate heat effectively, or if the tire is unable to resist the destructive effects of heat buildup, its ability to run at high speeds is reduced.

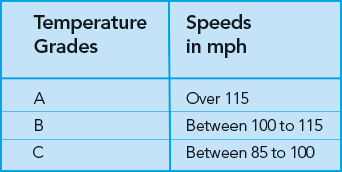

The grade is established by running an inflated test tire against a large diameter, high-speed laboratory test wheel. While there are detail differences, the UTQG test is similar to those used to establish speed ratings.

The temperature grades, from highest to lowest, are A, B and C. Every tire sold in the U.S. must be capable of earning a C rating which indicates the ability to withstand 85 mph speeds. Ratings of B and A represent higher levels of performance.

More importantly for most drivers, a higher rating signifies a more heat-tolerant tire. High levels of heat are generated at highway speeds, particularly with heavy loads. The temperature rating is particularly important in the southern states during the warmer months where speed-generated heat can drastically affect the structural integrity of a tire.

Most passenger tires today are A or B rated; certainly any tire with only a C is marginal. Temperature resistance should not, however, be confused with long-term overall durability; some of the things that help high-speed capability will make a tire less resistant to things like impacts.

What’s Next for UTQG?

Unfortunately, for all of the money spent to test, brand and label tires UTQG standards have not fully met their original goal of clearly informing consumers about the capabilities of their tires. Some engineers believe that mileage warranties may be of more use to the consumer.

A fuel economy rating will likely be added in the future. Tires sold in Europe already have them. For practical purposes, it will not be very helpful. It will affect performance tires because the high tire temperatures needed to develop traction also increase rolling resistance.

It is a multi-sided conundrum tire developers – and marketers – simply cannot escape.