Understanding the difference between tire pressure monitoring systems (TPMS) and automatic tire inflation systems (ATIS), as well as proper maintenance for both systems, is an important part of supporting a well-run fleet.

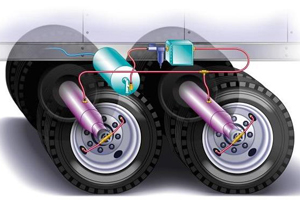

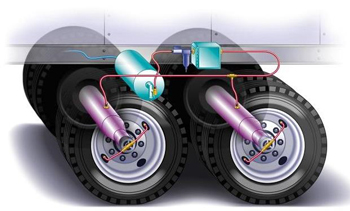

According to Al Cohn, director of new market development and engineering support for Pressure Systems International, “The function of TPMS is to alert drivers when a tire is low, but the system does not add air to the low tire. ATIS not only lets the driver know that a tire is low, but also adds air to the underinflated tire as the vehicle is running down the highway.”

Jon Intagliata, product manager of TPMS for Bendix Commercial Vehicle Systems, adds, “TPMS is a warning system that provides alerts when there is a problem. If maintenance is inspecting the vehicle and the OEM dash or the Bendix SmarTire display does not have an active warning or fault, then no action needs to be taken. If, however, there is an active alert or fault indicated by the system, action to correct the issue is required. Pressure or temperature warnings should be addressed accordingly.”

In addition to tire pressure and temperature warnings, there are a couple of system warnings that should be addressed by maintenance: low battery alerts and sensor faults. Prior to a sensor battery failing, a low battery alert is issued indicating the sensor will need to be replaced in the near future. Sensor faults are typically the result of a missing or damaged sensor that has stopped communicating with the ECU. Sensor faults should be corrected quickly, as the tire position that is faulted is not being monitored by the TPMS system.

Maintenance

Both TPMS and ATIS are low maintenance systems, notes Cohn. “TPMS requires a battery on each of the tire/wheel sensors. It is necessary to confirm that the signal from each tire sensor is being sent to the hand-held reader or to the reader in the tractor. ATIS requires that the shop confirm that the warning light on the front of the trailer is working properly. Also during normal PMs make sure to check for any system leaks (rotary union or hoses) using soapy water.”

In ATIS, the rotary union is the only wearable component that will need to be replaced. Soapy water will identify a rotary union that is worn out. They typically last three to seven years, or more. Check hoses for damage and leaks. With TPMS, confirm that the sensors are working properly.

“Shop staff should be educating drivers about how to use the system while they are on the road,” says Chris Steph, ITMS product manager for Stemco LP. “Features like visual low tire alerts (at the wheel end); in-cab alerts and the low-tire-logging feature are critical to understanding when action should be taken. Further, drivers should be trained on the specific actions they need to take for low tire alerts. Each fleet will tend to have slightly different policies or procedures, so this really becomes fleet specific for their in-house procedures.”

Steph suggests monitoring the following key elements:

a) Inspect hoses and valve stems for wear or abrasions

b) Inspect sensors for damage

c) If the maintenance tech has a HandBAT RF reader, sensors may be read and information inspected for diagnostic purposes

d) Inspect brackets/mounting hardware for excessive corrosion

“With many new technologies implemented by fleets, training is key,” Intagliata says. “Proper training of drivers, fleet maintenance personnel and/or third-party tire service providers is required to ensure a fleet is reaping the benefits from their investment in this technology. If drivers are required to maintain their tires, they should be trained on what each alert means and how it is addressed. If maintenance personnel maintain the tires, they must also understand this aspect.”

Additionally, he says maintenance personnel need to understand how to reprogram the system after sensors are changed or moved around, as well as how to install the sensor to ensure optimal service life. Once trained, drivers and maintenance technicians typically find maintaining the system to be easy, without requiring a lot of additional time during tire service. In the bigger safety picture, tire maintenance plays a crucial role in effective operation of the braking system and additional safety technologies that utilize the braking system, such as stability control and collision mitigation technologies. Optimum performance of the brakes and the safety system depends in part on keeping tires in good shape, and TPMS maintenance helps ensure that the tires will be ready to perform when needed.

Intagliata notes to make sure drivers and technicians know that, in general, if the TPMS has an active alert it cannot be fixed by adding or removing air from the tire, or if there is an active fault or temperature alert, the driver should report these issues to maintenance.

“A pre-trip inspection remains the most effective, simple and critical step you can take to identify low tires prior to getting out on the road,” Steph adds. “In addition, periodic visual inspections and functional system tests are recommended to ensure sensors are all in place and working as intended. Fleets may set their own inspection schedule, but every six months is a good rule of thumb.”

Training

Tire Pressure International, Bendix and Stemco all offer some form of TPMS and ATIS maintenance education.

Pressure Systems International offers hands-on training sessions and web-based training, says Cohn.

Bendix provides a series of maintenance and troubleshooting videos for the SmarTire TPMS (at www.brake-school.com), says Intagliata.

“We also offer a fleet/dealer initial system setup guide (BW8023). Since fleets typically purchase a variety of nameplates and set tire pressures based on their loading conditions, this guide comes in handy when programming the initial system settings. This is important to ensure that different vehicles are consistently programmed across the fleet, and that drivers and maintenance personnel are presented with consistent warnings and inflation pressures,” he adds.

Steph notes that Stemco offers maintenance training for fleet technicians in system installation, maintenance procedures, system operation, and support information and contacts.

Calculating ROI?

As for return on investment (ROI), many manufacturers say that the typical experience is that fleets realize payback on their investment in ATIS within the first year of ownership. Treadwear and fuel economy are all improved with running tires properly inflated all the time. Tire-related roadside service calls are significantly reduced by those fleets running ATIS on their trailers.

When it comes to determining ROI, it’s important to know your tire management goals, and choose the solution that best meets them. A fleet aiming to reduce service calls and severe blowouts may need a different solution than one aiming to stretch its long-term fuel efficiency and tread life.

Ideally, fleets would track tire cost per mile closely to understand the potential benefits of changes to their tire program. Yet often times fleets don’t have a steady tire CPM to use as a baseline. In that case, an assessment of blowout frequency and severity of irregular wear, along with a large tire pressure yard check survey, would be great exercises to go through to understand the impact of improper inflation.

The more consistent a tire’s use (routes, loads, regions, etc.), the better that tire’s performance will generally be. Additionally, the more frequent tire pressures are inspected and topped-off, the better fleets’ tire performance will be. In nearly all use cases, however, there’s a limit to the performance fleets can achieve when tire pressure is managed manually.

To take a tire program from good to great, most fleets would need to get much more sophisticated to account for ambient temperature effects on tire pressure, gauge inaccuracy, human error, tire heating throughout the day and during operation, road conditions, etc.

Calculating the ROI for an automatic tire inflation technology starts with an assessment of a fleet’s tire pressure maintenance program and the impact of downtime due to on-road tire failure. When putting pen to paper, an ROI calculation would typically focus on the cost impact in three areas: miles per gallon, tire life and blowouts/downtime.

Fleets can reference the numerous studies done to correlate severity of underinflation to a percentage reduction in fuel economy and tire life; these graphs are readily available. Easier yet, several suppliers have simplified this chore by creating customizable ROI calculators, though be sure to compute a full fleet-wide ROI as some only calculate the ROI for a single tractor-trailer.