Like most segments of the heavy-duty trucking industry, the fuel efficiency trend is rolling through tire retreads. While the conversation used to revolve around miles to removal, today’s talks are skewing toward fuel efficiency and total cost of ownership (TCO).

Like most segments of the heavy-duty trucking industry, the fuel efficiency trend is rolling through tire retreads. While the conversation used to revolve around miles to removal, today’s talks are skewing toward fuel efficiency and total cost of ownership (TCO).

“For most fleets, fuel costs represent the single highest non-payroll operating expense. So fewer stops for fueling translate into lower overall fleet operating expenses,” said Paul Crehan, director of product marketing, Michelin Truck Tires. “The fleets benefit in retread technology by way of new compounds and tread designs incorporated into the new offerings. With quality tires capable of being retreaded several times, the total cost of the tire asset over the long run is a benefit for the fleet providing they care for the casing.”

One of the biggest driving forces in fuel efficiency retread technology is the SmartWay program that has pushed retreaders to create new tire solutions and develop new products to meet the new standards, particularly for fleets operating in or doing business in California. Fleets that travel into California, are now required to run new tire and retreads that are SmartWay compliant; so, some of this specific business has shifted to SmartWay-approved products. Of course, that spills into the rest of the country.

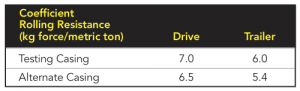

Many tire retreaders offer efficiency-focused retreading designs that are similar to new tires. SmartWay-verified retreads, for example, are subject to a rigorous testing method put forth by the Environmental Protection Agency (EPA), which includes testing using the ISO 28580 method, on an 8.25-in. test rim, a 2-meter drum (or a drum that follows the Drum Diameter correction protocol). The load used is 85% of the maximum load of the tire capacity and a capped inflation pressure corresponding to the maximum load capacity as marked on the sidewall for single load application. A minimum of three retreaded tire tests are required and the average test result for rolling resistance coefficient must be at or below the following targets:

“Thanks to advances in rubber technology and tread design, fuel efficient retreads are routinely offered to fleets as an economical and environmentally-sound alternative to new tires,” said Harvey Brodsky, managing director of the Retread Tire Association. “Retreaders can offer more tread designs than new tire dealers, as well as designs specific to the usage required by the trucking fleet.”

The challenge for manufacturers developing SmartWay tires is to combine fuel savings and maintain long mileage, as well as reducing the tire rolling resistance, said Giampaolo Brioschi, product marketing manager for Marangoni.

Taking a look at manufacturer offerings, Goodyear’s fuel-efficient retreads compliment its Fuel Max truck tires, which use fuel-saving compounds and specialized tread designs to lower tire rolling resistance, helping to reduce fuel consumption, explained Todd Labbe, general manager, commercial retreads, The Goodyear Tire & Rubber Co. The company’s UniCircle Technology offers fuel-saving benefits through its solid, seamless construction and UniCircle Tread Applicator’s laser positioning system. Goodyear offers the G392 SSD UniCircle and G394 SST UniCircle retread products—SmartWay-verified versions of which will be available soon.

With the launch of new tires, comes the launch of new retreads. Michelin has recently unveiled retreads for its latest tire offering including the Michelin X Line Energy D, Michelin X One Line Energy T and Michelin X One Line Energy D.

Continental’s ContiLifeCycle develops its ContiTread retreads based on new tire design and compounding to achieve comparable performance results from new tires to retreads. The Ecoplus line of ContiTread, includes several closed- and open-shoulder drive and trailer retreads. “Continental is constantly exploring innovation within all aspects of retreading,” said Scott Miller, ContiLifeCycle Manager. “Our equipment division colleagues at ContiMachinery are developing key pieces of retread equipment, our IT group has created CLC Soft to improve data gathering and tracking within the retread plant and our R&D engineers are always investigating various improvements to retread processing and products.”

Marangoni’s SmartWay-verified Energeco line offers a variety of tread depths for dual axle configuration, trailer design; dual axle configuration, closed shoulder drive design; dual axle configuration, open shoulder drive design; and wide-base axle configurations. The Energeco line sports its Ringtread technology (spliceless and double contour profile for a superior fitment on the tire) together with the Energeco compound in order to have no compromise between fuel saving and mileage.

Bandag Retreads are as fuel efficient, or in some cases better, than new tires, according to the maker, as long as a premium fuel-efficient original casing is used such as a Bridgestone M710 Ecopia or R197 Ecopia. The Bandag B710 FuelTech, B197 FuelTech, B135 FuelTech, and B835 FuelTech match the Bridgestone new tire counterpart. The recently launched the B799 is the retread complement to the Bridgestone M799.

By retreading these casings, fleets can extend the benefit that the original casing provides, explained Matt Schnedler, retread product marketing manager, Bridgestone Commercial Solutions.

“Tires that are retreaded by top quality retreaders will have a lower adjustment rate than comparable new tires and at a saving of as much as 50% of the cost of a new tire,” Brodsky commented.

Self-Sealing Solutions

Fleets that run self-sealing tire solutions, such as Goodyear’s DuraSeal Technology, which is the only built-in self-sealing technology in the industry, can rest assured that retreading is still a viable option for these tires. Goodyear’s Todd Labbe explains: “Thousands of Goodyear DuraSeal truck tires have been successfully repaired and retreaded since Goodyear introduced DuraSeal Technology in 2006. In fact, DuraSeal’s bright yellow color makes it easier for retreaders to detect punctures in the casing’s tread area during the casing inspection process.”

Retreaders should follow the guidelines of the new tire and retread suppliers to ensure proper retreading procedures are followed.

Self sealing casings follow the same guidelines as non-self-sealing casings. However, if a self-sealing tire is damaged, then that can require a slightly different retread process to ensure that the damage is repaired properly. Additionally, if the self-sealing feature includes uncured rubber, care must be taken to avoid contamination with other tires/retreads. The retreader must follow the guidelines of the new tire and retread suppliers.

Going Wide

Wide-base tires are gaining traction in fleets for due to their promise of increased efficiency and additional payload transportation. With such tire success comes retreading solutions. Wide-base tires can be effectively retreaded to offer additional cost savings and lower the total cost of ownership for this asset. Like other retread offerings, retreaders claim that wide-base retreads offer similar fuel efficiency and performance as new tires, as long as the proper buff radius is applied.

Wide-base tires are gaining traction in fleets for due to their promise of increased efficiency and additional payload transportation. With such tire success comes retreading solutions. Wide-base tires can be effectively retreaded to offer additional cost savings and lower the total cost of ownership for this asset. Like other retread offerings, retreaders claim that wide-base retreads offer similar fuel efficiency and performance as new tires, as long as the proper buff radius is applied.

Damage Control

Try as you might to keep your casings pristine, the reality is that a casing may be damaged when out on the road. Before tossing in the tire towel, you should check with your retread and repair dealer. Each manufacturer and retreader has guidelines that will determine which injuries can be repaired and ensure proper service life and safety can be achieved. The ability to repair and retread typically depends on the size of the damage.

“Many injuries to the casing such as sidewall cuts, punctures and bead damage can be repaired. The size of these injuries and the application the tire will be used in are deciding factors in determining whether or not the tire can be repaired,” Bridgestone’s Schnedler stated. “It is imperative that retreading technicians inspect the tire thoroughly to make that determination.”

Goodyear Authorized Retreaders, for example, have the capability to perform section repairs, spot repairs, nail-hole repairs and non-steel bead area repairs in the crown area and sidewall, as defined by Goodyear’s retread process manual.

Daily tire inspection is important; attention should be directed at sidewall areas for new cuts or damage to the tread area to ensure there are no penetrations from foreign objects in the tread area or stone retention, which can cause stone drilling to the belt package.