We all have been in this situation: You’re looking at some removed OTR tires with the customer standing next to you looking for answers. You think you know the reason for the removal of the tires being inspected, but then you see something else that could also be a reason.

Now you have to figure out what came first – Problem A or Problem B.

You have to understand the potential reasons for the removal of tires in order to properly help the customer understand the true reason for the removal. But the most important thing is to show how to prevent the same thing from happening again.

The second highest cost in any mining or quarry operation is generally tires. This is why it is important to understand the removal reason for each tire coming out of service.

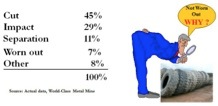

Removal reasons vary by site, but the majority of tires (93% as you will see in Figure 1) are removed for reasons other than being worn out. When a cost is placed on the unutilized tread of tires prematurely removed from service, the customer will better understand the importance of having a solid maintenance program in place.

The reasons for removal at each site may change, but in the end, closely monitoring the site, training the operators and managers as to what to watch out for, and teaching them how to prevent the same thing from happening will increase tire performance immediately. Plus, the changes will have a very positive impact on the customer’s bottom line.

Three Ws of Tire Care

Being able to confidently explain to the customer why the tire failed and how to prevent the same cause from happening again puts you into a different category. You’ll be seen as someone who values customers’ business by looking for ways to decrease their overall tire cost.

As you may recall, in my last article, I wrote about the importance of not being a salesperson, but a consultant or analyst. This does not just apply when providing a tire to your customer. It is just as important when a tire is removed from service.

Discussing the three “Ws” with the customer provides an excellent opportunity to share your knowledge and interest to help improve their operation. What does each one of the “Ws” mean?

• Why – Exactly what caused the tire to be prematurely retired? Was it just one thing or a combination of multiple problems?

• When – Exactly when will action be taken to address the concern found and to document the improvements as they happen? This can range from training the operators to changing the haul roads to implementing an air pressure program – or all of the above.

• Who – Exactly who will be responsible for ensuring the issues are acted upon to correct the situation? Assigning people or teams to the issue will get the focus in the right place and create a better chance that the issue will be corrected.

Having in place a process to reduce incidents of premature removal of tires helps to keep everyone on the site focused on improvement.

Minimize Tire Damage

Now let’s get into two of the main reasons for removal of OTR tires and the best way to address the issues with your customers. Of course, each customer is different, so you will need to figure out how best to approach a particular customer.

Cuts, impacts and incorrect air pressures are most likely the major reason for removals at any operation. Period.

The cutting of a tire cannot be totally eliminated due to the conditions that haul trucks and loaders operate in daily. Focus needs to be on not just the roads, loading and dumping areas, but on the grades of the inclines and declines, proper drainage of water on the roads and the type of road dressing used. All these areas – plus air pressure – will affect how a tire performs. Daily tire inspections can help prevent an early failure.

If the cut is minor and does not go deep into the tire, make sure the object is removed and then continue to run the tire while closely monitoring the cut to ensure it is not growing or that air is not escaping.

If a cut is deep or the object is still embedded in the tire and the problem is caught early, suggest removing the tire, inspecting it, and, if needed, sending it out to be repaired.

A minor cut on the outside of the tire can turn into a rock cut separation if it is not dealt with right away. Be sure to work closely with your repair tech to ensure that the best practices are being followed.

An impact break in a tire happens when there is excessive energy loading (the impact) beyond the breaking strength of the carcass. The result is an immediate loss of air (blow out) and/or damage to the cords inside the tire, causing a separation. Either way, the tire will need to be taken out of service. It may be repairable and put back into service, or repairable to process for retreading.

Ways to reduce impacts are:

• Monitor haul roads, loading and dumping areas to ensure they are clear of rocks and other objects that could damage a tire.

• Review the loads hauled and determine if overloading is an issue. If that is the case, then work with the site personnel to correct the issue.

Air Pressure

Air pressure is a major factor in the life of the tire. Make sure all tires are properly inflated to carry the loads required. The tire manufacturer can provide you with the correct air pressure for the loads.

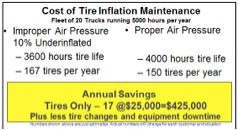

Underinflation will cause the carcass to flex more, which could start breaking down the compounds. This will eventually cause the tire to fail well before wear out. Explaining and showing the tire customer the savings potential (see Figure 2) with proper inflation is critical to a successful tire program.

Whether the operator is measuring tire life by actual service hours or distance driven, the negative impact of underinflation is the same:

• 90% of the proper inflation level will shorten the life of the tire by 10%

• 80% of the proper inflation will reduce the life of the tire by 25%

• 70% of the proper inflation will reduce tire life by 50%.

Overinflation is just as serious as underinflation. When the casing does not flex properly to absorb the energy of the object being run over, it can do damage resulting in an impact break or other premature cutting of the tire.

When doing the out-of-service inspection analysis, look at the process as a great opportunity to share your knowledge with the customer. Knowing the operation through site surveys, air pressure checks and monitoring loads is invaluable during these inspections, and will help you clearly show the customer why any tire was removed before its time.