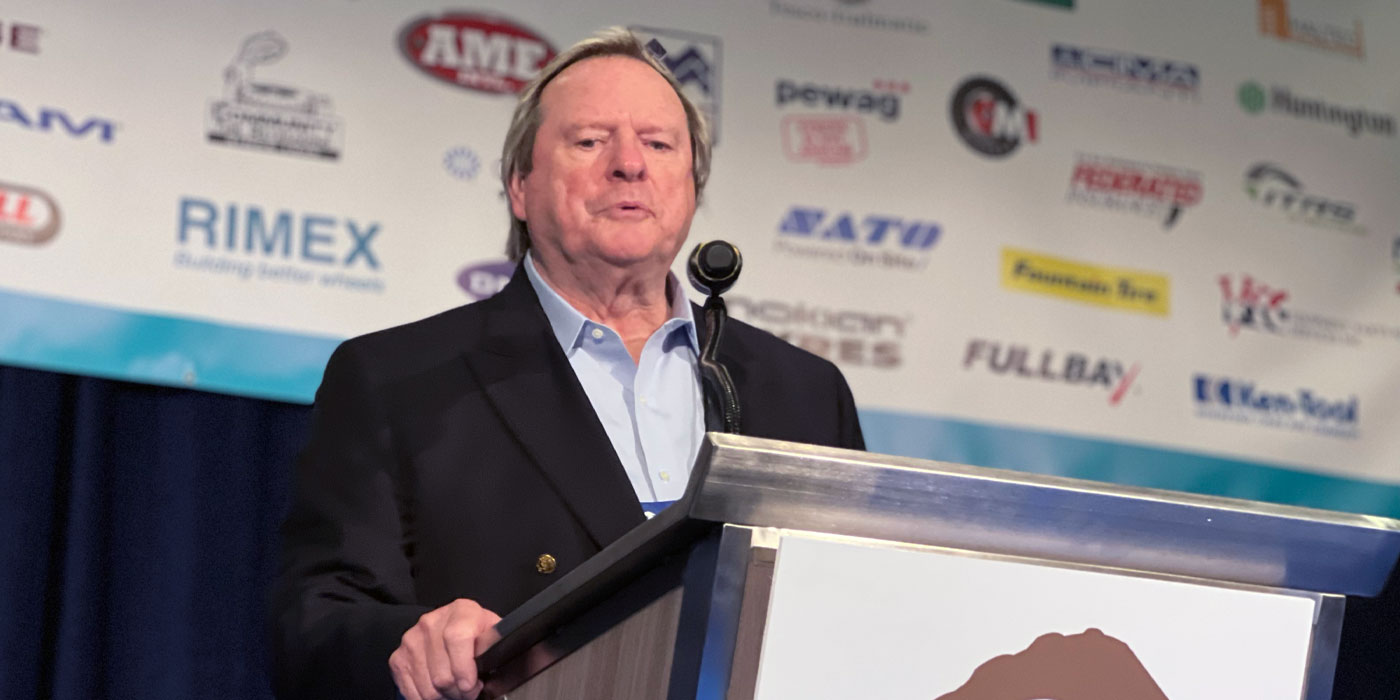

Recently, former TIA president Peggy Fisher, who is well-known and respected throughout the trucking industry, wrote an article that was, well, a little disparaging and generalized about China-made radial truck tires sold in the U.S.

I have every confidence that you’ll either know about it already, or can find it.

Twice within the last week, the Retread Tire Association has blast emailed two letters from tire industry folks taking umbrage with Ms. Fisher’s assertions about the quality and utility of China-made radial truck tires, which currently make up well-more than 40% of the U.S. replacement market.

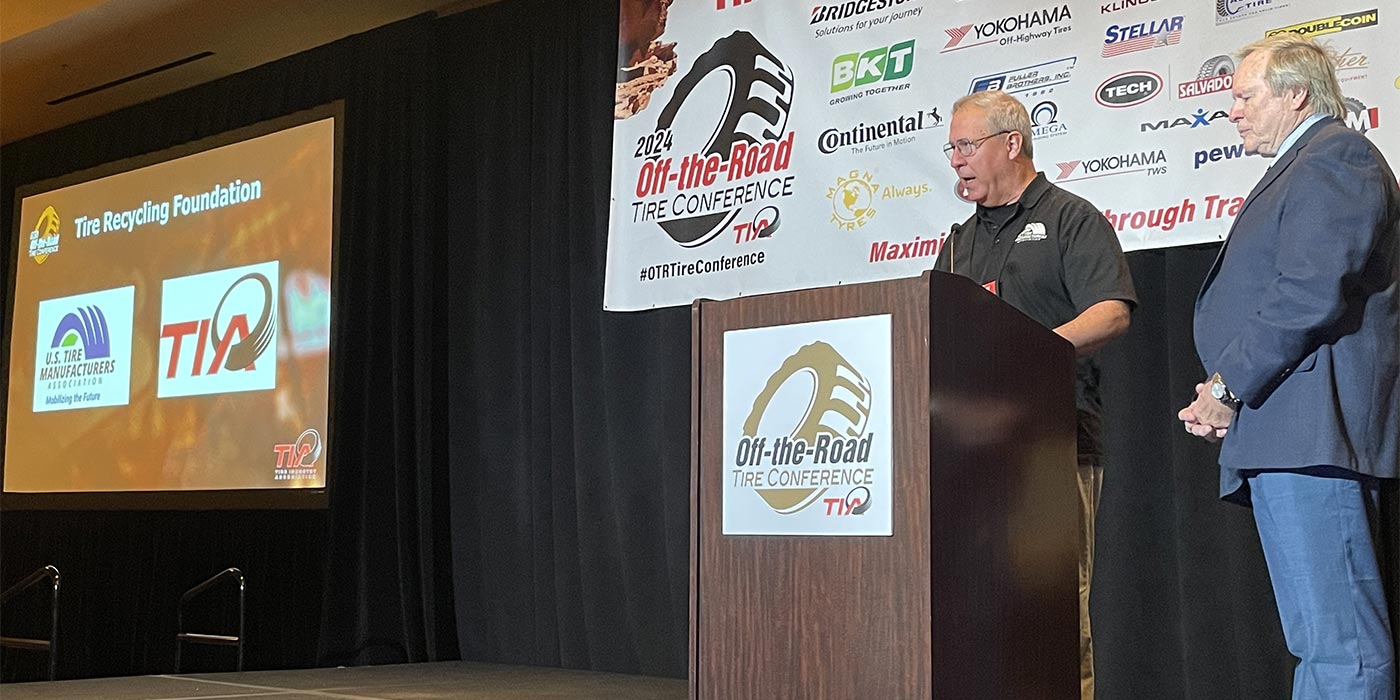

Here are those two letters, thanks to RTA managing director Harvey Brodsky:

Harvey,

Thanks for bringing my attention to the article mentioned in your email. Peggy Fisher makes some viable points. However, we are a strategic-sourcing partner for several of the largest tire dealers (Kal Tire, Fountain Tire, OK Tire, Coast Tire and Benson Tire) in Canada. All of our truck tire brands are made by three manufactures in China – Aeolus, Sailun and Triangle. Certainly, we feel that all of these brands/manufacturers are consistent and reputable.

Their manufacturing plants are clean and modern (more so than some Tier 1 manufacturers). Our owner has been working with Chinese suppliers for 25 years and has developed very good relationships. We have an in-house engineering department that works collaboratively with the Chinese factories and engineers on product development, tire design and product testing. This ensures product quality and consistency.

Dynamic Tire in Canada, and Husky Tire in the U.S. are responsible for administering product warranty issues on behalf of the manufacturers. This includes the original tread life and through the second retread on most brands.

Yes, we are one of the few distributors that stands behind their Chinese product. There are many traders that you can’t find when it comes to warranty.

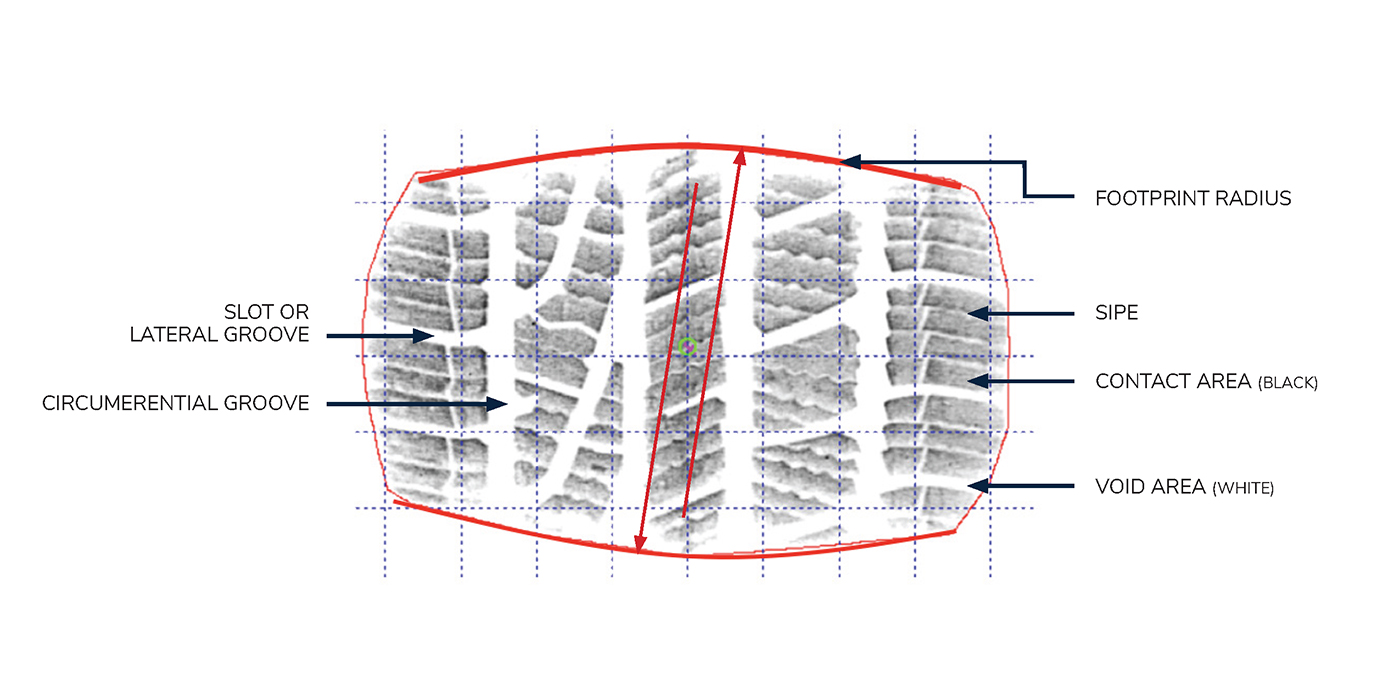

Through our retread facilities we have gather data on all brands of tires we have retreaded/rejected from Tier 1 down to Tier 4. We have non-retreadable tire data on over 50,000 casings. You (and Ms. Fisher) would be surprised at the quality of Chinese truck tires. Based on the data collected, there are some Tier 1 brands that experience some workmanship and material defects that Tier 3 and Tier 4 brands do not.

We can speak from experience because our retreading customers are primarily the same dealers who purchase the Chinese manufactured tires from us. We do not hesitate to retread any of the brands we sell. We would be glad to take some of the casings that Ms. Fisher has referred to as disposable. Any fleet that has taken that position is foolish in my opinion.

If the casing is deemed sound by proper inspection techniques and will last for the life of the retread, it is a retreadable casing as far as I am concerned regardless of brand. I think you would agree.

On behalf of retreaders throughout North America, let’s all do one another a favor: don’t simply dismiss Chinese casings as non-retreadable. Perform the proper inspection and retread what is retreadable. We are all sadly mistaken if we think that the Chinese-manufactured tires are going away. As Ms. Fisher indicates, the quality will continue to improve.

Sincerely and Passionately,

Al ‘Ace’ Eagleson

Director, Commercial Truck Products

Dynamic Tire Corp.

Harvey,

There is a similarity in our current reaction as tire dealers and retreaders to the Chinese truck tires as there was when the “radial” truck tire first came on the market many years ago.

There is a significant change coming about in the market. This is what happens in the market place. We must adapt and change with the changing market. As a provider of the TreadWare software for retread shop management, we see the data on many casings. It is changing. Even Tier 1 manufacturers have certain tires that show up as having a history of problems. Liner failures, premature bead cracking, excessive sidewall bulging, etc., happen with every brand at some point.

Tracking the data, observing it and using it are the ways to have factual information. Our observation of the data over the last several years shows us that the quality of tires produced around the world continues to improve.

The fact is that “Things watched do better.” Trucking companies, tire dealers and retreaders that provide and utilize tire management services and tracking repeatedly see better performance in almost every brand.

The fact is that many truck tires produced in China are improved and retreadable, multiple times. As the retreading industry adapted to radial tires, we must now adapt to tires produced in China. We must improve inspection and repair techniques. We must follow and track the performance of different brands.

The fact is that many Chinese tires are being retreaded successfully while providing value to the user and profit to the retreader. If money can be made retreading intermodal tires, it can surely be made retreading the new generation of Chinese radial truck tires.

At TreadWare, we will continue to help the independent retreader watch and track the data.

Clayton Van Kleeck

TreadWare