Summer is a great time of year for vacations, family gatherings and closely monitoring your customer’s OTR tires. With more demand on your time, sometimes it is easy to let the site inspections and air pressure checks slide. This is when trouble will start for many customers, even though they may not see the negative result for months.

In a previous article, I briefly covered the importance of doing detailed site inspections. We cannot talk enough about this, even if we are highly experienced tire professionals. This is not just checking air pressure, which I discussed in my April article, but also doing haul and loading studies plus ton-mile per hour reviews. Taking the time now to perform these inspections will keep your customers from putting heat on you later.

Prior to starting your study, make sure you meet with the site planners. Have them explain the different hauls not just today, but what might change in the next 90 to 120 days. This will allow you time to look at the potential demands on the tires and ensure that the correct compound or tire is being installed on the equipment.

Site Studies

Many people see things differently when looking at the hauls, loading practices and overall maintenance of the site. This is why you need to work with the facts. After all, there are many factors that affect the actual tire life.

• Load vs. Tire Life – Hauling more is not always better, especially if the tires are overloaded. Built-in scales on the new equipment are a great help in understanding the tonnage being loaded and carried. But if there are no scales on the equipment, what do you do next? You might ask the site engineer or find a chart that provides you some weights of the material being loaded and hauled. For example, sand is about 3,100 pounds/cubic yard and stone is generally around 2,500 pounds/cubic yard.

It also is important to know if the density of the material will be changing, just like their hauls. Once the material density is known, as well as the size of the bucket loading the equipment, you then will have a number to work with. True, this number is only an estimate, but you have to have something to work with until the actual loads are known through weight studies.

What effect does weight have on tire performance? The general rule is a tire that is 10% overloaded will have a 10% reduction in life. At 40% overloaded, the life of the tire is reduced on average by 40%. Overloads can cause casing fatigue, radial cracking, liner failures, reduced wheel life and a greater chance for impacts.

• Grades – No, we are not talking about a score on a test, but the degree of the grade coming out of the main loading area. Trying to find out the exact grades in degrees, let alone percentages, can be more difficult, so uncovering what the designed grade is for the haul roads will help to understand what they might actually be. Besides 0%, the best grade to reduce tire slip is between 5%-8%. A higher percent of grade will cause more traction issues, especially when the haul roads are wet.

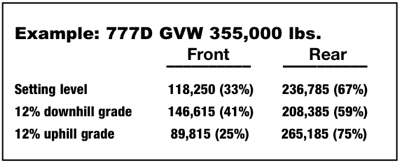

Besides slippage, weight transfer also is an issue. For every 1% of grade, the load will transfer 2%. This is important to know, particularly for downhill, loaded hauls since two tires (instead of four) are carrying the majority of the load, as shown in Figure 1.

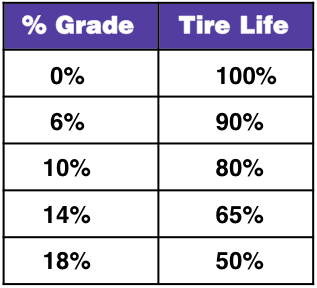

All the above statements have a significant effect on tire life, as shown in Figure 2. As you can see, it does not take much of a grade to affect the overall tire performance. These numbers are estimates, but can provide some great talking points when analyzing the customer’s tire performance and what recommendations can be made to enhance tire performance.

• Underfoot Conditions – Poor underfoot conditions can be very costly and need to be closely monitored, not just by you, but also by the operators, site supervisors and operating management. Many premature tire removals can be avoided or greatly reduced by implementing standard underfoot procedures.

Make sure the roads, as well as the loading and dumping areas, are clean from spillage and are well-graded. Take time to discuss this with the proper people at the operation so that action can be taken before a tire issue occurs. Improper sized shot rock for road dressing can reduce tire life by as much as 40%.

Water and rubber do not work well together. Water is a lubricant, but, counterintuitively, will help an object to cut the tire very easily. This could equate to a 60% decrease in tire life. Demonstrations always get the point across, so next time you see a lot of standing water at an operation at which the trucks and/or loaders are operating, bring out a water bottle and knife. Spray an area of a removed, non-mounted failed tire (do not try this on a tire that is mounted and inflated on a wheel) and cut the rubber with the knife. You will see that the rubber can be cut very easily.

Now try to cut the tire without water. You will find it is very difficult to cut the tire. Keeping the roads as free from water as possible will provide an immediate benefit to the customer. In the end, good haul roads equal a much lower cost per hour.

• Supers in the Haul Roads – Everyone knows the importance of high-banked curves at the NASCAR tracks and the same theory holds true for haul roads – just not as steep. Designing good supers (about 3%) in the curves helps to eliminate high-lateral tire forces, which will extend the casing life. Other advantages the operation will see, besides reduced wear and tear on both the truck and tires, are faster cycle times (could be a negative) and cleaner haul roads due to less spillage.

You never want to see a negative super in the haul road, as the high-lateral force created by the weight transfer will affect tire performance. Haul roads with moderate curves and no supers would see about a 10% decrease in potential tire life. Severe curves with no supers could reduce tire life by 20% or more.

• Cycle Times – Knowing the ton-mile per hour (TMPH) is the most important part of a site study. This is basically the average tire load times the average tire speed. Each manufacturer has a basic formula for figuring the TMPH of their tires, so it is important to review the manufacturer’s OTR engineering databook. The information provided in different companies’ databooks is excellent and if you have not taken time to read through them, I suggest you spend some time reading and understanding the information available to you.

Observing your customers’ operations, knowing what to look for and, most importantly, taking time to explain both the good and bad items found, will enhance the longevity of the tires and your customers’ confidence. Your customers are very busy this time of year as well, and they need your assistance to monitor their operations and share your findings.

Hopefully, they will listen and implement an improvement plan, which will have positive paybacks in the future. When this happens, you can better enjoy your summer vacations.