Everyone selling OTR tires has at some point encountered tires that have been subjected to excessive speed, overloads and heat. Of course the customer generally will not admit that any of this happened to the tire and they expect either the dealer or manufacturer to step up and handle any shortfall performance of the tire.

This is why doing a complete site study prior to selling a tire to an all-new customer or one that is just starting a new job is important to the success of the tire’s performance.

But taking the extra step and doing a Ton-Mile-Per-Hour (TMPH) study in advance will ensure that the customer can maximize tire performance and continue to value you as the dealer of choice to handle tire needs. This article will focus on the steps to determine tire TMPH yourself and give you the tools to obtain the information. The goal here is for you to understand how to collect the data and, most importantly, how to obtain the actual TMPH value for the operation.

Manufacturers always talk about TMPH values for their tires, but how many people really know what this means or how to figure the actual requirements? TMPH measurements and ratings are used to help determine the correct tire and compound to install on the customer’s equipment. All tires have a rating and the numbers for each can be obtained from the tiremaker.

TMPH measurements and ratings are used to provide guidelines when determining the correct tire to place on the equipment so that the tires do not overheat or wear out faster. There are many variables that need to be monitored while doing the haul study to ensure that the tires can operate in all the possible site applications that the tires could face.

It is very important that you know all the hauls that the tire will operate in order to properly figure the TMPH. The haul with the highest TMPH requirement must be used to determine the proper tire and compound to be placed in the operation.

What is TMPH?

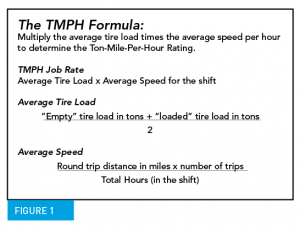

TMPH is a formula that looks at the average tire load multiplied by the average tire speed. The formula allows you to calculate the load, speed and time factor that fits the tire temperature limits. Eliminating premature tire removal due to misapplication is the target everyone is looking to accomplish.

TMPH values will change based on the tread depth and tread compound of the tire. The deeper the tread, the lower the TMPH value. This also holds true to the compound. A heat-resistant compound provides the highest TMPH value, while a cut resistant compound has a much lower number.

For example on a 2400R25 the readings would look something like this (based on the compound): Heat Resistant = 270, Standard = 205 and a Cut Resistant Compound would come in at 160. Getting the correct value for the site will help to achieve the best tire performance.

Many manufacturers have in their Databooks details as to how the TMPH calculation should be computed. The examples they use are very detailed and make it much easier to understand the process necessary to obtain the job TMPH. Manufacturer Databooks basically show the same process and explanations. Figure 1 was copied from the Goodyear Databook, and it provides an explanation of TMPH job rate and the information required to obtain the correct number.

All of the databooks that I reviewed said that for haul lengths in excess of 20 miles one way, you need to consult the manufacturer’s representative. In the Bridgestone Databook, the tiremaker states that the TMPH values were computed at 100°F ambient temperature and at a maximum speed of 35 mph (50km).

Getting Going

So where do you start? First, you need an app or another device to gather data with accuracy. There are many GPS apps available that can track the distance, running and stopping times, and average speed, and profile the haul route. I use the Gaia GPS app, but there are many apps available that can provide the same information.

Once you have a means to gather the information, place your smartphone with the GPS app recording or a GPS device that can collect data into the cab of the haul truck. Then let the equipment run. It is a good idea that you follow the unit through the different haul cycles so that you can obtain better information of the actual hauls. The data collected will provide a lot of valuable information that can be used to help complete the TMPH formula.

Then you need to find the average tire load, starting with the empty vehicle tire load, in pounds or tons. This information can be obtained on the Internet or by contacting the equipment dealer. The other number you will need is the loaded vehicle weight. This will have to come from the customer or from a recent weight study that may have been completed. Be sure to note and adjust for sideboards, tailgates or modified truck beds; any haul truck modifications will change the vehicle load.

Next is to obtain the average shift speed. You have the average miles for the round trip haul. The other data required is the total trips per shift and the hours worked per shift, including all breaks.

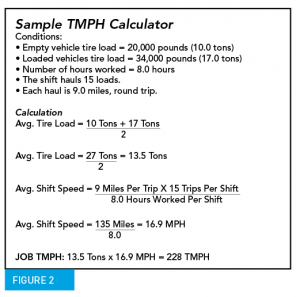

Once you have collected all of the data listed above, you’ll have enough information to work out the TMPH. If you are calculating the numbers manually, go to the manufacturer’s databook to find the calculation process. (see Figure 2, which comes from the Goodyear Databook.)

Another way to figure out the TMPH is using an app from Maxam Tire. It is a very useful feature to calculate the TMPH and one I use often. The summary comes instantly from the data you inputted.

Tire Heat Issues

To avoid heat issues, the haul truck tires must have a TMPH rating higher than the Job TMPH number calculated. This can be done by considering tread designs and compounds best suited for the application and that exceed the TMPH value.

If the tires currently on the machine have a rated value less than the TMPH you calculated, you will need to tell the customer to: 1) Reduce the load being hauled, 2) Reduce the speed that the equipment is currently operating at, or 3) Change to tires with a higher TMPH rating.

Any of these recommendations will be difficult for the user to accept; the first two suggestions will affect production and the last one can cost money especially having to change out good tires. But if nothing is done the performance expectations for the tires will not be met, thus increasing the cost per hour of the tires.

A new TMPH study needs to be done when changes in the fundamentals are made, such as the length of hauls changes, the material being hauled is different (lighter/heavier), or a new truck with a different size tire is brought to the site.

If you have any questions or want to confirm that your numbers are correct it is always a good idea to contact your tire supplier and ask them to help verify your information. This way you’ll know that the information you give to your customer is correct.

With the changes that many of your customers face from the different haul requirements – especially if they are a contractor – knowing what the TMPH requirement is up front will prove to be invaluable. This way when tires are replaced you are installing the correct compound and tread to maximize tire performance for the specific job requirement.

Understanding customer requirements based on facts is of great value, and should allow you to secure their business for the long run.