China has become the world’s largest tire producer. This is not a boastful statement, but the plain truth. China has more top-level domestic producers with more production facilities than any other country, making everything from bicycle tires to giant OTR radials, under both domestic and well-known international badges.

The country now has the world’s largest car parc, one that recently topped the U.S. and is still growing rapidly. On the truck and bus side, China has a huge need for high-technology radial tires and a huge appetite for bias-ply tires.

And even with the U.S. and U.K. as its largest export customers (for now), its domestic growth potential remains largely underestimated.

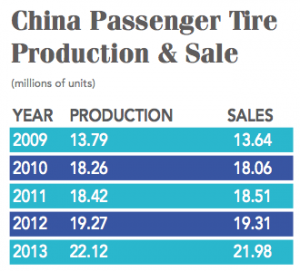

In recent years, China’s automobile industry has shown great momentum as more and more Chinese people have become vehicle owners. In 2013, China’s car production reached 22.1 million units and sales surpassed 22.0 million cars, year-over-year growth of 14.76% and 13.87%, respectively.

In 2013, Bloomberg reported that China’s vehicle population reached some 240 million, half of which were passenger cars. By comparison, in 1999 China had fewer than 20 million privately owned passenger cars – fewer than the country produced domestically last year. Four years ago, IHS reported that car ownership in China was 31 per 1,000 residents – compared to 424 per 1,000 in the U.S. In 2013, China’s number rose to 69 per 1,000 people.

The fast growing car parc has fueled the rapid development of China’s tire industry. According to the China Rubber Industry Association statistics, Chinese domestic tire production has grown from 250 million units in 2005 to 529 million in 2013 – a total yield that ranked first in the world.

In 2014, China’s tire industry will continue that growth trend as the competition within the domestic tire market will further intensify. At the same time, the industry needs to take caution and properly balance production capacity with market demand and raw material price changes.

China’s tire production enjoyed double-digit growth in 2013 and expects to see the same growth this year. As the Chinese automobile industry sees 8% to 12% growth in 2014, the domestic OE tire industry should see at least similar growth. The replacement market will likely grow at an even greater rate.

A Good Harvest

Last year, the profit level of the Chinese tire industry was better than ever, but the profit growth rate showed a clear downward trend. The main reason is a disparity between the drop off in natural rubber prices and the prices charged for finished tires. That difference remains in 2014. With tire prices continuing downward and NR prices stabilizing, the difference will be narrowed, reducing profits.

Still, it is expected that in 2014, the overall Chinese tire industry will have a good harvest. The industry’s overall profit growth rate will fall to 20% while tire profit margins will drop to below 4%.

World’s Largest Exporter

With economic globalization, the rapid improvement of tire production technology, the impact of industrial transfer by tire giants, and the strong development of its automobile industry, China is also now the world’s largest tire exporter.

According to Chinese government statistics, in 2012, China’s tire industry exported of $43.8 billion in tires, a year-over-year growth of 7.2%. In 2013, the Chinese total tire exports rose to $15.63 billion (not including two-wheeler tires), of which passenger car tire exports reached $5.88 billion, and truck/bus tire exports totaled $8.06 billion.

Xu Wenying, the vice president and secretary general of the Chinese Association of Automobile Manufacturers, analyzed radial passenger tire shipments to the U.S. Xu found that the U.S. was the largest customer of Chinese tire exports, taking in more than 1.15 million tons. The export volume for the U.K., the second largest destination country, is less than 200,000 tons.

Technology Growth

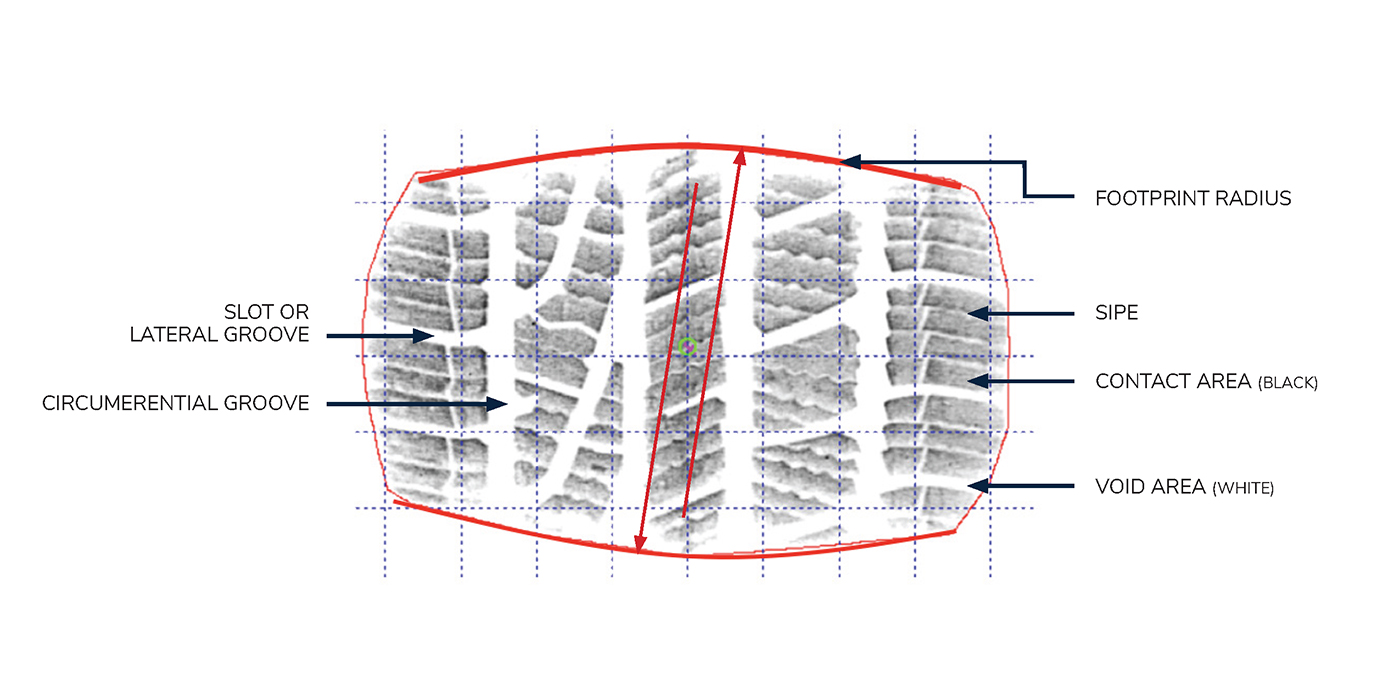

In recent years, several new production technologies emerged in the Chinese tire industry, many of which have reached world-class levels. Thanks to an increase in R&D investment, an expansion of the scale of research work, and significant promotion to tiremakers of the importance of advancing technology as a way to improve their market competitiveness, the tire product development cycle is continuously being shortened.

Take Shandong Linglong Rubber Co. as an example. Its ultra-low profile, wet skid resistant, low noise radial tire has achieved major breakthroughs in ride comfort, environmental protection, safety and handling. The Linglong 6 series – including the Greenmax HP010 and Greenmax Ecotouring – have passed European Union ECE noise certification, won the fuel saving award and reached an international advanced level. All Linglong eco-friendly tires meet REACH requirements, and on the truck/bus side there are more than 50 Linglong products that have received U.S. EPA SmartWay certification.

In 2011, Linglong tires placed well in Finland Test World Oy’s summer tire test report, ranking ahead of several world-known tire brands. Chinese tire companies may not be dominant in individual tire test programs, but by building comprehensive performance, they can win the game.

Compared with more advanced tire manufacturers, Chinese tiremakers have invested limited resources in R&D because they are restricted by the financial strength and scale of their businesses, the level of scientific research done and other factors. As a result, the overall technology level is still low, and the results show on the sales side; around 70% of the Chinese passenger car tire market is occupied by foreign or joint venture tire enterprises.

Therefore, China’s tire industry is calling on its members to develop in the direction of high-end tires, with high technology content and high added value. The R&D direction should include run-flat, low noise, fuel savings and environmental protection.

With technology improvement and the continuing development of the Chinese automobile industry, China’s domestic passenger tire industry seeks to grab a larger share of the domestic market within a few years.

Possible U.S. Tariffs

Chinese tire enterprises are preparing to deal with the possible punitive tariffs by the U.S. government. In 2013, Chinese tiremakers exported tires to the U.S. valued at $3.34 billion, involving more than 1,000 enterprises. If the U.S. imposes punitive tariffs calculated at a 60.15% dumping margin and a 25.73% subsidy rate, based on rumors, the impact on Chinese tiremakers would be far more significant than that during the last round of administrative tariffs.

Chinese tire producers believe that the potential additional tariffs is not reasonable as they will not reflect true market conditions and will only serve to greatly increase the tire purchase cost for U.S. consumers.

These Chinese tire enterprises have been actively collecting evidence to respond to the Commerce Department investigation and USW charges.

Among the points against additional tariffs, Chinese enterprises argued that China’s tire export growth mainly benefits from the growth of the U.S. auto industry, not otherwise, and that lower priced NR is the primary reason for lower cost China-produced tires.

Shandong Yongsheng Group is one of the largest tire exporters to the U.S. In order to deal with this new trade barrier, they are ready to collect the relevant evidence to prove that they have not been dumping or received government subsidies, as well as evidence they say will show that it has not caused any damage to the American industry.

At the same time, Chinese tire enterprises have all started to prepare alternative methods to maintain their presence in the U.S., including the following:

- Build factories in other low-tariff countries

- Improve product performance

- Expand the scope of export to other countries and regions

In addition, some Chinese tire companies have taken steps to upgrade their the level of performance from their products:

- Triangle, Linglong, Sailun and Double Star have become OE suppliers of all-steel radial tires for FAW and China Heavy Truck

- Triangle now supplies supporting radial tire engineering for Caterpillar, Terex and Volvo

- Triangle has become the first Chinese domestic semi-steel radial tire manufacturer to become a well-known international brand

- A Linglong UHP tire has entered the global procurement system for world-class automakers, including GM, Ford, Brazil Hyundai, Russia Renault Nissan and Tata.

Regardless of how the tariff situation plays out, the Chinese tire industry will continue its rapid growth – both in size and technological strength. The domestic market demands for technology, quality and price will be no different than any other market, and the size potential poses both great opportunity and daunting challenges.