Bearings are the forgotten brake service item.

Bearings are the forgotten brake service item.

Today’s cars and light trucks don’t require much maintenance. Spark plugs last 100,000 miles, long-life coolants can go five years or 150,000 miles (whichever comes first), and some filters have no recommended replacement interval (such as in-tank fuel filters). But sooner or later, one thing all vehicles eventually require is brake work.

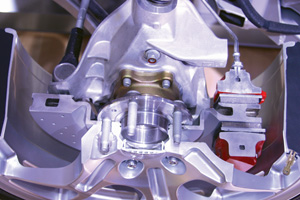

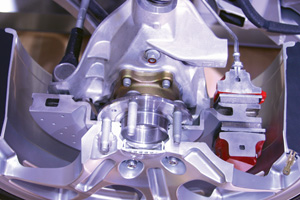

A cutaway of a wheel and hub. Different driving styles will dictate how long brake linings will last.

Brake pads wear every time the brakes are applied. The larger and heavier the vehicle, and the more often it is driven in stop-and-go traffic, the faster the pads wear out.

Aggressive driving also accelerates pad wear, as do poor driving habits like waiting until the last minute to apply the brakes when approaching a traffic light or stop sign. Mountain driving, towing an trailer or hauling heavy loads also can accelerate pad wear and reduce the service life of the pads (and shoes if the vehicle has drum brakes in the rear).

Another factor that has accelerated brake wear (especially rear brake wear) in certain late model vehicles is the change to electronic brake proportioning. The proportioning valve that normally reduces hydraulic pressure to the rear brakes has been eliminated so the rear brakes will handle a higher percentage of the brake load and be more aggressive. The antilock brake system performs the job of brake proportioning by keeping an eye on how the rear brakes are behaving. If the rear brakes start to lock up when braking hard, the ABS system kicks in and cycles pressure to the rear wheels to prevent them from skidding.

This approach helps the vehicle stop in a shorter distance, but also increases rear brake wear dramatically.

In vehicles with a conventional proportioning valve, the front brakes typically wear two to three times faster than the pads or shoes in the rear. Consequently, a vehicle may go through one or two sets of front pads before all four brakes need to be relined.

That’s not the case with some late model cars that have electronic brake proportioning. The rear brakes may actually wear out before the front brakes. This can make some people think there is something wrong with their brakes because they’ve never had a vehicle where the rear brakes wore out before the front brakes. But that’s the new “norm” for some late model cars.

It’s hard to say how long a set of brake linings will last on any given vehicle because of differences in driving styles and how the vehicle is used. On some full-size SUVs that are driven in an urban environment, it’s not unusual for the front brakes to wear out in as little as 30,000 miles. Ditto for the rear brakes on certain import vehicles that have electronic brake proportioning. At the other extreme, some vehicles may rack up 80,000 or more miles of highway driving before the pads are worn out and have to be replaced. If you had to pick an average mileage where most cars probably need brake work, it would be 50,000 to 60,000 miles.

What Needs to Be Replaced

When a vehicle gets its first brake job, it may only need a set of pads. That’s the $59.95 brake job special that’s often advertised to attract customers who may need brake work. In reality, the brakes often need much more to restore them to like-new condition.

If only the front pads are worn, and the rotors are in relatively good condition (no pedal pulsations due to uneven wear or hard spots, no cracking or heat discoloration, and no severe rusting), the vehicle owner can usually get by with minimal repair expense. Most shops will usually resurface the front rotors anyway to assure they are smooth and flat (and to reduce the risk of a comeback due to a noise or pedal pulsation complaint). Rotors must be replaced if they are worn to minimum thickness specifications, or cannot be resurfaced without exceeding the minimum machine specifications.

Calipers usually need no attention the first time the pads are replaced as long as they are not leaking and there is no sign of sticking (uneven wear between the inner and outer pads). Even so, the caliper bushings and mounts should be inspected for wear or corrosion and lubricated with brake grease to assure smooth operation. In the case of high-mileage calipers (80,000 miles or more) or ones that are more than 10 years old, the calipers often have to be rebuilt or replaced because the seals are worn or leaking. Same for the wheel cylinders on vehicles with rear drum brakes.

Speaking of rear drum brakes, the condition of the springs and other hardware inside the drum is often overlooked when the shoes are replaced. Springs can weaken and corrode with age, and should be replaced on high-mileage vehicles to assure proper shoe operation and return.

Like rotors, drums need to be inspected for wear, cracking or other problems such as bellmouthing, out-of-round or hard spots. Drums can be resurfaced as long as the inside diameter does not exceed the maximum ID specifications.

The brake hoses and steel lines should likewise pass inspection on the first brake job with no problems in most cases. But as the age of the vehicle goes up, so does the need for replacing these parts. Rubber hoses that are more than 10 years old may be brittle, cracked or leaking. Steel lines can also become badly corroded with age. A failure of a brake hose or steel line can be dangerous because it results in a loss of brake pressure in that brake circuit. All vehicles have a tandem master cylinder that splits the brake system into two separate systems (both front brakes, and both rear brakes, or diagonally paired brakes RF and LR and LF and RR). This supposedly provides backup braking in case one side of the system fails. But don’t count on it. If the front brake circuit fails, the rear brakes alone may not be able to stop the vehicle in a safe distance.

A brake pedal that slowly sinks when held under pressure usually indicates a worn master cylinder. The only fix for this is to replace the master cylinder.

It’s also important to flush and bleed the brake system after the brakes have been relined or other parts have been replaced. Brake fluid has a limited service life and after several years of service it is often contaminated with water. The corrosion inhibitors in the fluid also are depleted over time. So to restore the fluid’s boiling resistance (which drops as moisture contamination goes up) and its ability to inhibit corrosion, it’s essential to flush out the old fluid, and replace it with new fluid (DOT 3 or 4 as specified by the vehicle manufacturer). Bleeding the brakes removes air (which is necessary for a firm brake pedal), but it does not necessarily replace all of the old fluid in the system — especially if only one or two brake lines are bled. Bleeding must also be done in the sequence specified by the vehicle manufacturer to assure all the air is out of the system. On some vehicles, they may require using a scan tool to cycle the ABS solenoids and/or opening bleeder valves on the ABS hydraulic modulator to vent air bubbles.

Wheel Bearings

Most late model vehicles have sealed wheel bearings that require no adjustments or maintenance. Most wheel bearings should last up to 150,000 miles or more. So many do-it-yourselfers (and technicians) think there’s no need to pay any attention to the wheel bearings when doing a brake job. Wrong! Though the bearings do not require any maintenance, they should be inspected to make sure they are capable of doing their job safely.

A bad wheel bearing may not always make itself known by chirping, squealing or making noise. Many do make it obvious that they have reached the end of the road, but others just roll silently along until they suddenly fail.

A wheel bearing failure can have serious consequences if it occurs while driving at highway speeds and the vehicle loses a wheel. That’s why the wheel bearings should always be inspected for looseness or roughness when the brakes are serviced.

The wheel bearings in most vehicles are designed for normal, light-duty driving. They are not designed to handle unusually high cornering forces or excessive loads. Consequently, many passenger cars and even some light trucks and SUVs have double ball bearing wheel bearings inside their hubs rather than stronger roller bearings. It’s a cost-cutting step that automakers use in many applications. But when a vehicle is driven hard and subjected to unusually high cornering loads, it puts a lot of strain on the wheel bearings and can cause premature bearing failure. This is a common occurrence on police cars, race cars, even taxis and delivery vehicles.

The traditional way of checking sealed wheel bearings is to rotate each wheel by hand while listening and feeling for any roughness or play in the hub. On late model vehicles with sealed wheel bearings or bearing cartridges, there should usually be little or no play, and certainly no roughness or noise.

The crude way to check for play is to raise the vehicle so the wheel is off the ground, then grab tire at the 12 o’clock and 6 o’clock positions and rock the tire back and forth. If there is any noticeable play, the bearings are loose and need to be replaced.

If there is just a little play, the amount of play can be measured with a dial indicator. Place the dial indicator against the hub and rock the wheel in and out. As a rule, there should be no more than .005 inches of play in the bearings if the bearings are good.

Another check is to rotate the tire by hand while measuring play, but be careful not to confuse rim or hub runout with looseness in the bearings. As a rule hub, runout should be .0015 inches or less, and no more than .002 to .003 inches of runout at the lip of the rim. If there is too much runout, try reindexing the wheel on the hub, or remove the wheel and measure runout on the rotor or hub itself.

On vehicles that have antilock brakes with a wheel speed sensor built into the hub assembly, there’s another way to check for wear and internal hub problems. The sensor ring is part of the bearing assembly, so excessive play, wear or looseness in the hub will often cause the sensor ring to wobble as it rotates. Wheel speed sensors are very sensitive to changes in the air gap between the tip of the sensor and the sensor ring. Consequently, a worn bearing may cause an erratic signal that sets a Wheel Speed Sensor (WSS) code and turns on the ABS warning light. Or it may not.

A scan tool that can access the ABS system and display individual voltage or speed readings, or a digital storage oscilloscope can also be used to observe the WSS outputs to detect bearing wear. Any variations in the WSS output would be most noticeable while turning sharply or cornering under a load. The speed of the inner wheel will obviously read slower than the outside wheel when rounding a curve. But if the WSS signal suddenly drops out or changes drastically, it could indicate wear or too much play and movement inside the sealed hub assembly.

Internal corrosion inside a sealed hub assembly can also play havoc with the WSS signal. The wheel bearings may still be okay, but corrosion on the sensor ring can cause an erratic speed signal. This can set a WSS code and turn on the ABS warning light. Various GM and Ford models have had such problems over the years. On applications where the WSS sensor is removable, the fix has been to remove and clean the sensor, then add some zinc corrosion inhibitor to the hub cavity. On applications where the sensor is integral and cannot be removed, the only fix possible is to replace the entire hub assembly.

On older vehicles with serviceable wheel bearings, the bearings should be cleaned, inspected and repacked every 30,000 to 50,000 miles. There are still a lot of these older vehicles on the road, and the bearings on most are poorly maintained because few motorists know the bearings require maintenance.