According to R. L. Polk, the average age of the vehicles on U.S. roads was 9.2 years in 2007, with 41% of the vehicles 11 years or older. This high median age is a good reason to consider the condition of the brake fluid and bleeding procedures when performing maintenance or repairs.

Maintenance or repair of an anti-lock brake system can require the opening of the hydraulic system. Any time the hydraulic system is opened, air can be introduced into the lines and components. This means air can be introduced into the system when a master cylinder, brake pressure modulator valve (BPMV), calipers, wheel cylinders, brake hoses or lines are replaced.

Any maintenance or repair procedure should begin at the master cylinder. A low fluid level can indicate worn pads. Pad wear is automatically compensated by fluid displacement in the caliper bore.

When worn pads are replaced, the fluid in the caliper bore must be removed. One method of doing this is to open the bleeder screw and force the fluid into a container. This is recommended for contaminated fluid in order to prevent possible damage to the BPMV.

Another method is to force the fluid back through the BPMV and into the master cylinder. If you decide to return the fluid to the master cylinder, make sure that the master cylinder has not been topped off. The condition of the caliper pistons and seals will dictate whether the caliper needs to be replaced or if just new pads must be installed.

From 1994 to the present, approximately 58% of domestically produced vehicles were equipped with ABS. The brakes in most vehicles equipped with ABS can be bled using a conventional pressure or vacuum method, provided no air has been introduced into the BPMV.

The replacement of the BPMV can require specific bleeding procedures to clear the lines of any air accumulated. If air has entered the modulator, a pressure bleeder and scan tool may be required to purge the motor driven pump and solenoid valves. Always refer to the vehicle manufacturer’s recommended bleeding sequence, as this may vary from one application to another depending on how the system is configured.

Alldata, Identifix, Mitchell1 and OEM websites are a good source for this information. The following is a recommended procedure for a Bosch ABS 7 system:

• Pressurize the system to 35 psi.

• Select the Automatic Bleed Procedure on the scan tool.

• The scan tool energizes and cycles the BPMV solenoids for one minute.

• The scan tool will instruct you to bleed each wheel.

• The pump runs and cycles the valve for one minute.

• This is repeated for each wheel.

• The scan tool cycles the ABS solenoids for 20 seconds.

• Relieve pressure at the bleed tool.

• Then check pedal height and feel.

• Check for and clear any trouble codes.

No matter which method is used, the ABS system will be affected. When the pads are replaced, the piston usually is pushed into the caliper bore, where it will require the brake pedal to be depressed, possibly to its full stroke, to re-engage the pads to the rotors.

A variety of vehicles, such as the Cadillac STS, Toyota Prius and others, use a push-button start system where the key is a transmitter that activates all of the vehicle’s systems when the key is in close proximity of the vehicle.

If the transmitter key is activated and the ABS has a pedal travel sensor, a trouble code can be set for excessive pedal travel. The code will set when the pedal is depressed to reengage the pads to the rotors.

Brake Failures

Some unknown brake failures that cause accidents can be attributed to moisture contaminated fluid. After the failure and the vehicle’s brakes are inspected, no apparent mechanical fault can be found.

The fluid level is normal. The linings are within specifications. The hydraulic system appears to be working properly. The pedal responds normally to application pressure. For some reason, the fluid may have become overheated to the point where it boiled and caused the brakes to fail. This kind of sudden brake failure due to fluid boil may occur in any driving situation that puts undue stress on the brakes, such as a sudden panic stop followed by another, mountain driving or towing a trailer.

Several vehicle manufacturers also recommend brake fluid changes for preventive maintenance. Honda recommends a flush and fill every 25,000 to 30,000 miles. Subaru also recommends a 30,000-mile brake fluid change. BMW and VW recommend the fluid should be changed every two years.

The fluid base is ethylene glycol, which is hygroscopic and can absorb 1% to 2% of its weight in water per year. The actual amount of water depends on the condition of the system components and, most importantly, the hoses that can experience moisture intrusion as they age.

It also depends on the type of brake fluid, humidity and driving conditions. DOT3 brake fluid contains corrosion inhibitors that, with time and moisture, are depleted. Corrosion can affect the operation of the entire system from the master cylinder, ABS valves and motor-driven pump to the caliper. Moisture also affects the boiling point. One percent water in the fluid can lower the boiling point of a typical DOT 3 fluid to 369F. Two percent water can push the boiling point down to around 320F, and 3% will take it all the way down to 293F, which is getting dangerously close to the minimum DOT and OEM requirements.

Testing

There two methods for testing fluid contamination:

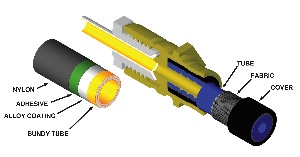

One method uses a test strip available with copper-testing technology, used for an indicator of corrosion occurring in the brake system. Most brake tubing is manufactured using the Bundy process of using copper-coated, low carbon steel to form a double wall tubing with protective coatings to prevent corrosion to the outer surface of the tube. These coatings can consist of a simple hot-dipped alloy coating of zinc and aluminum to the addition of a polyvinyl paint or extruded nylon to the zinc and aluminum coating.

Moisture and the depletion of the corrosion inhibitors in the fluid are the main sources of the fluid breakdown. Corrosion causes the copper to be leached from the tubing and deposited in the brake fluid. The test strip changes color to indicate the condition of the fluid based on its copper content. The test strip is a moderately priced, clean and easy method for testing the fluid with each strip being a one-time use that can be part of the repair order.

The second method that can be used is a refractometer. This is an instrument that can range in price from $100 to $300. It can be used for coolant, as well as brake fluid.

It samples the moisture content of the fluid by how light is bent as it passes through the fluid and prism of the instrument. A sample of the fluid is placed on the sample prism and the daylight cover is placed over the sample. The sample is the read by looking through the eyepiece.

The drawback to the refractometer is that the prism and daylight cover should be cleaned and flushed with distilled water after each use to ensure the accuracy of the next reading. It also should be calibrated periodically. The calibration of the refractometer is checked by placing two to three drops of distilled water between the prism and daylight cover and allowing the water to spread across the entire surface of the prism without any air bubbles or dry spots.

The refractometer is made to measure the fluid at room temperature, 20ºC (68ºF). Allow the test sample to sit on the prism and daylight cover for approximately 30 seconds to equalize the temperature of the sample and refractometer before taking the measurement. The figure above shows the reading with a clean, dry prism and daylight cover (top). The bottom of the figure shows the reading with distilled water. The instrument will come with instructions to calibrate.

Replacing Fluid

A top down replacement may be the best means of replacing the fluid. The master cylinder reservoir can be emptied and filled with new fluid. This will allow the new fluid to pass through the master cylinder and BPMV before entering the brake lines, hoses and calipers.

Changing brake fluid periodically could greatly reduce the risks associated with moisture-contaminated brake fluid. It can extend the life of customers’ brake systems and in the long run, especially if their vehicle is equipped with ABS, save a costly repair of the brake pressure modulator valve.