The tire industry – and the world – was vastly different a century ago, when Cooper Tire & Rubber Co. got its start.

The automotive industry was still quite young in 1914, when brothers-in-law John F. Schaefer and Claude E. Hart purchased M and M Manufacturing Co. in Akron, which produced tire patches, cement and repair kits.

A year later, they purchased Giant Tire & Rubber Co. of Akron, a tire rebuilding business, and in 1917, moved the combined business west to Findlay, Ohio.

The origins of the Cooper name go back to 1920, when Ira J. Cooper, a director for the company Schaefer and Hart founded, formed the Cooper Corp. By 1946, the organization’s name was changed to Cooper Tire & Rubber Co.

The origins of the Cooper name go back to 1920, when Ira J. Cooper, a director for the company Schaefer and Hart founded, formed the Cooper Corp. By 1946, the organization’s name was changed to Cooper Tire & Rubber Co.

But for Cooper, success means more than longevity. In an industry that requires constant evolution in order to survive – and a true spirit of innovation in order to thrive – the tiremaker has successfully navigated the last century and is poised to continue that trend.

While there are many aspects of the company’s strategy that have contributed to this success, perhaps none have been more important than technological innovation. Cooper veterans share insights into what technological advancements helped shape Cooper into the company it is today, and where the tiremaker is headed in the next century.

Early Innovation

Before examining the logic behind certain technological innovations and their effects on the industry, it’s important to know that Cooper has always approached the market differently than its peers. By selling only through independent outlets – rather than mass merchandisers or company stores – and focusing solely on the replacement tire market, the tiremaker set itself apart early on.

In the early 1930s, the company’s truck and bus tires were among the few brands made with Egyptian cotton cord and a patented double breaker – a tire with two extra plies of fabric cord. In addition to using the latest in tire construction, the Cooper “Armored Cord” innovation became well-known in the industry and gave the company a competitive advantage, according to Cooper.

The tiremaker began using “cold rubber” in tire tread – a new synthetic rubber – in the 1940s. According to Greg Bowman, manager of innovative technology at the company’s Global Technical Center in Findlay, this refers to the process polymer manufacturers used to make the synthetic rubber.

“In the 1940s there was a transition from a hot emulsion styrene-butadiene rubber (SBR) to a cold emulsion process. When they made that change, the properties of the rubber significantly improved – that translated into a more durable tire that would wear longer,” he says, adding, “It was a big game changer for the industry at the time. Cooper was one of many companies that moved over to it around the same time.”

Passenger car tires produced at the time included the Cooper Safety Grip, Cooper Cushion-Ride and Cooper Soft-Aire, as well as the Cooper All Duty – a truck, bus and heavy equipment tire.

During the 1960s, development of new and timely products was the hallmark of Cooper’s marketing philosophy, according to the company. In 1960, two new passenger tires were introduced: an all-nylon cord body mud/snow designed tire called the Cooper Weather-Master Sno Trac, and a new “super-mileage” tire called the Cooper Lifeliner Nylon Premium.

In 1961, the company saw sales improve largely as a result of merchandising new and improved tire lines, as Cooper used the slogan, “Best Known for Quality.” A significant development during that year was the introduction of Cooprene – a new polybutadiene synthetic rubber – that offered a substantial improvement in tread wear characteristics and tire life, according to Cooper.

Over the years, Cooper placed strong emphasis on marketing research to identify its direction for product development, including tires such as the Cooper Wide Runner “70 Series” tire, offering a low profile and wide tread for performance. This tire was made with polyester and fiberglass cord – marketed as belt-reinforced – and was typical of the company’s approach to product innovation in the late 1960s, according to Cooper. Still, at that time, it also continued R&D efforts on radial ply tires.

“The 1960s and 1970s were a really interesting time in the tire industry because there was a move from bias tires to radial tires,” says Chuck Yurkovich, senior vice president of global R&D. “The very unique thing about the polyester and fiberglass cord approach was that essentially, it was an interim step between the two types of tires.

“By introducing bias-belted tires, we were able to bring better performance to the tire product portfolio and introduce a tire that was compatible with the majority of automobile suspensions and configurations at that time,” he adds.

The Move to Radialization

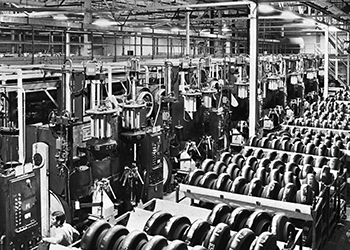

According to Dave Dryden, director of materials development, the shift to radial tires was roughly a seven-year transition for the industry.

In 1973, Cooper started radial tire production with the most popular 13-, 14- and 15-inch sizes using a steel belt and a polyester carcass. By 1978, Cooper had introduced a line of radial tires with several advanced engineering features.

“The move to radial tires was a dramatic change in tire construction and performance,” Yurkovich explains. “Both tire manufacturers and vehicle manufacturers had to adapt because it required development of new tire designs, constructions and materials, but also a redesign of automobile suspensions. The vehicle had to change with the tire to be compatible with that improved performance.”

He adds that tiremakers could not build radial tires on the same equipment that was used to build bias and bias-belted tires – requiring a hefty investment.

“Cooper had an advantage because we had the capability to design and fabricate our own equipment,” Yurkovich says. “We had the capability that facilitated that change, and even though the investment was relatively high, it was easier for us to do that than some of the other tire companies.”

Dryden noted that not every tire company took Cooper’s approach. “Some tried to make radial tires using the old equipment; that was not very successful,” he says, adding, “Those that tried to stretch the old equipment to work on the new tires failed fairly obviously, and those who were a little more progressive and made new equipment or modified their equipment were successful.”

“It was one of those landmarks, those lines in the sand where if you didn’t make the right move at the right time, you were left behind,” Yurkovich explains. “Some tire companies did suffer because of that. Cooper made a timely change in configuration, which was beneficial to us.”

Entry Into High Performance

In 1987, Cooper introduced its first high performance tire – the V-rated, 50-series Cooper Cobra VR50 Radial G/T. It offered a new center groove design that represented a significant departure from standard competitive performance tire tread patterns – a design that would soon become widespread throughout the industry.

Dryden, who was part of that tire’s development team, said the unique center groove design “was an industry innovation that, in hindsight, we could have capitalized on more.”

“That idea of a wide center groove was very successfully marketed by some of our competitors with the launch of the rain tire concept in the early 1990s,” he adds. “Soon, the market was flooded with all-weather rain tires. There were a number of patent lawsuits in that era; fortunately for Cooper we had already been in the market with that wide center groove four or five years prior to that.”

In 2003, Cooper greatly expanded its product line in high performance tires, and for the first time, introduced ultra-high performance products. Utilizing the Cooper Zeon name as its UHP flagship, by the end of that year, the company had captured about 5% of the high performance replacement tire market in North America.

“At that time, the UHP market was becoming a bigger segment of the overall market,” Dryden explains. “For Cooper to be successful and move forward, we had to capture a piece of that market – the Zeon product was successful in its performance and met that niche of the market, so it allowed us to grab a piece of it.”

The Zeon line was Cooper’s first foray into 19-, 20- and 22-inch sizes, its first Y speed-rated product, and its first offering of 30 and 35 aspect ratios, he adds.

In 2011, Cooper introduced the most new products in its history with the addition of four new premium tires: the Discoverer A/T3, an all-terrain SUV and light truck tire; the Discoverer S/T Maxx, a true commercial grade traction tire; the Cooper Zeon RS3-A, a UHP all-season tire; and the Cooper Zeon RS3-S, a UHP summer tire.

This year, Cooper set a new company record for the number of new products launched in a single year, introducing the CS5 premium touring tire – available in two options: the CS5 Ultra Touring and the CS5 Grand Touring; Discoverer SRX tire for the SUV/CUV market; the Discoverer X/T 4, an all-terrain tire developed specifically for Canadian drivers; and the Discoverer A/TW SUV and light truck tire.

Looking Ahead

Cooper will increase the pace of new product development moving forward, according to Yurkovich. “It is very critical that we are able to develop and introduce better products every year, and the plan is to keep that pace up into the next several decades.”

While that pace may seem dizzying, he explains that because Cooper has the technical abilities – working with new materials, utilizing computer modeling and on-vehicle testing, and using its test track near San Antonio – and works collaboratively with external companies and suppliers, rapid development of new technology is possible.

“You’ll find us coming to market with things that are developed jointly with a supplier or an external company, where we can leverage each other’s capabilities to do something new and different,” Yurkovich says.

A large part of Cooper’s current focus is the use of renewable biomaterials in production. Through a $6.9 million government grant, the tiremaker is working with a consortium of partners to develop a domestic source of natural rubber from the Guayule plant.

“It would be a huge benefit for the industry in North America because it would reduce our dependence on foreign imports and help make the tire industry a little more independent from wild fluctuations in cost based on the availability of natural rubber,” Yurkovich notes.

Cooper has already produced a few prototype tires made using Guayule-derived rubber, which are currently undergoing testing.

The tiremaker also is involved in the Program of Excellence in Natural Rubber Alternatives (PENRA), which looks at the use of Russian dandelion as a rubber source.

Through a separate $1.5 million government grant, Cooper is working to develop a lightweight, fuel-efficient tire – one that weighs 20% less than a standard tire while offering equal or better performance, and that offers a 30% reduction in rolling resistance in order to boost vehicle fuel economy by 3%.

Linking Past With Present

Among the strengths that have allowed Cooper to succeed over the years, according to Yurkovich, are the company’s speed to market and desire to work efficiently with suppliers and customers.

“We do things more quickly than our competitors do; we are much more efficient at developing and introducing products in a technically competent way,” he notes. “We are very easy to work with from a customer standpoint – that was part of the model of the company early on – and we are very good for suppliers to work with. We aren’t vertically integrated as a company, so we work with a lot of external material suppliers to bring new materials to the market. Those three things have always been a strength of the company, and we still leverage them today.”

Yurkovich explained that during the last 100 years, Cooper had some innovations and moved very quickly with certain technologies – like the center groove tire – “but we were in the pack, moving forward with other tire manufacturers.”

“Cooper in this century has become a different and better company in that we are more devoted to innovation and development of advanced technology,” he says. “There are cases in which we’re leading with industry firsts (the research mentioned above, for example).”

He adds the tiremaker has become an international company and is moving rapidly toward global status through plant acquisitions, greenfield facilities and joint ventures around the world. Cooper now has multiple technical centers – in Findlay, China and England – and has “become much more technically adept, keeping our speed to market but developing technology that allows us to compete effectively head-to-head against anyone in the industry.”

The company also has entered the OE market, first with Roush Performance Products’ 2009 modified Mustangs, then in 2013 with Ford’s Focus SE and Titanium models.

“Tire companies vary quite a bit in how they approach technology,” Yurkovich says. “Often, you’ll find that the top tire companies in the industry – the tier ones – lead development and make the investments in new technologies, while the smaller companies – tier two, or several of our peers in the industry – don’t invest a lot in innovation and are working more on getting OE or replacement business, just making a statement in the market. We have some unique characteristics in that we are investing in innovation and technology very aggressively.”

Having made the move from an American company with humble beginnings to a global powerhouse that is cranking out new products and technologies to benefit the entire industry, right now is an exciting point in Cooper’s timeline.

We look forward to watching – and reporting to you – Cooper’s progression during the next 100 years.